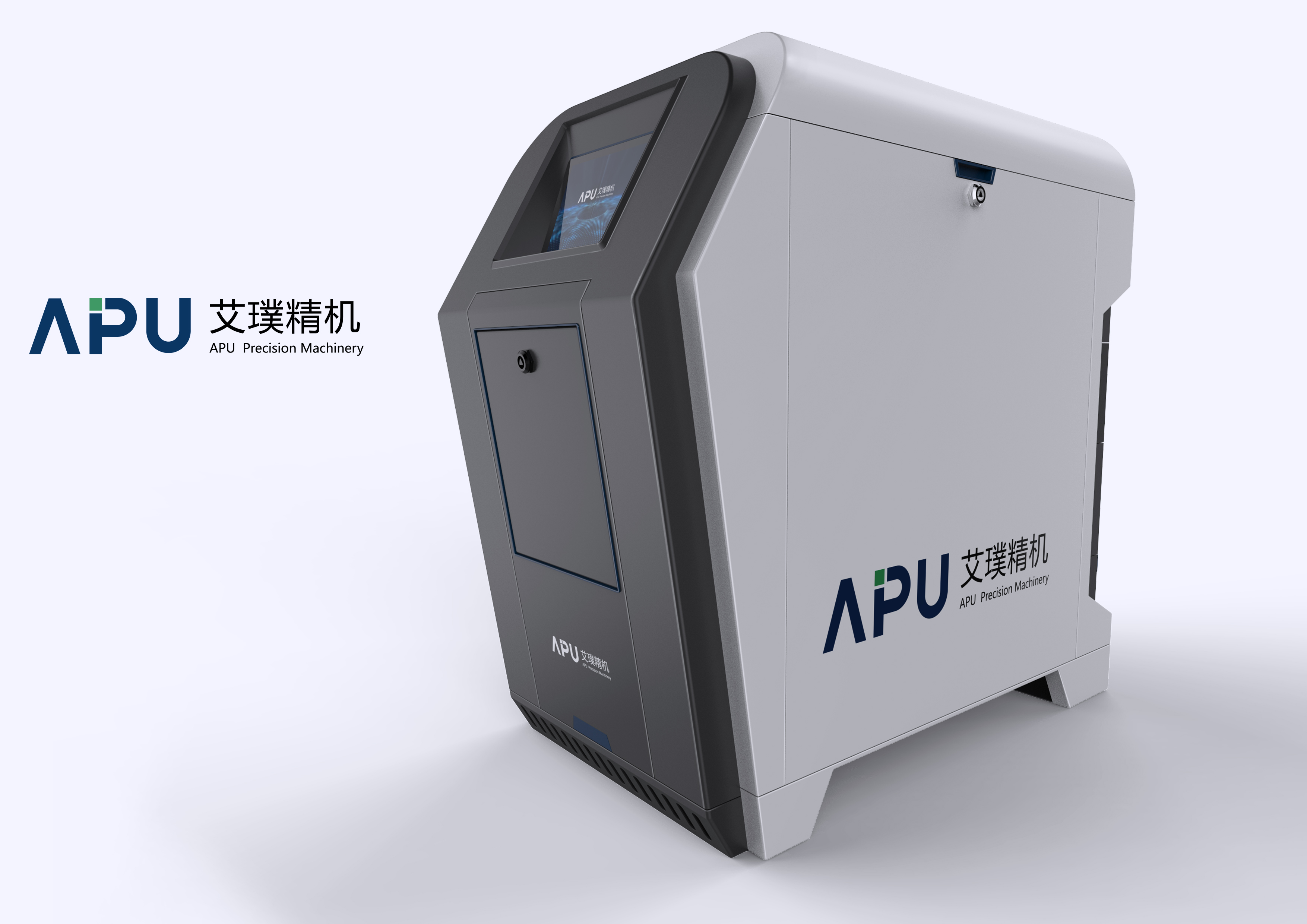

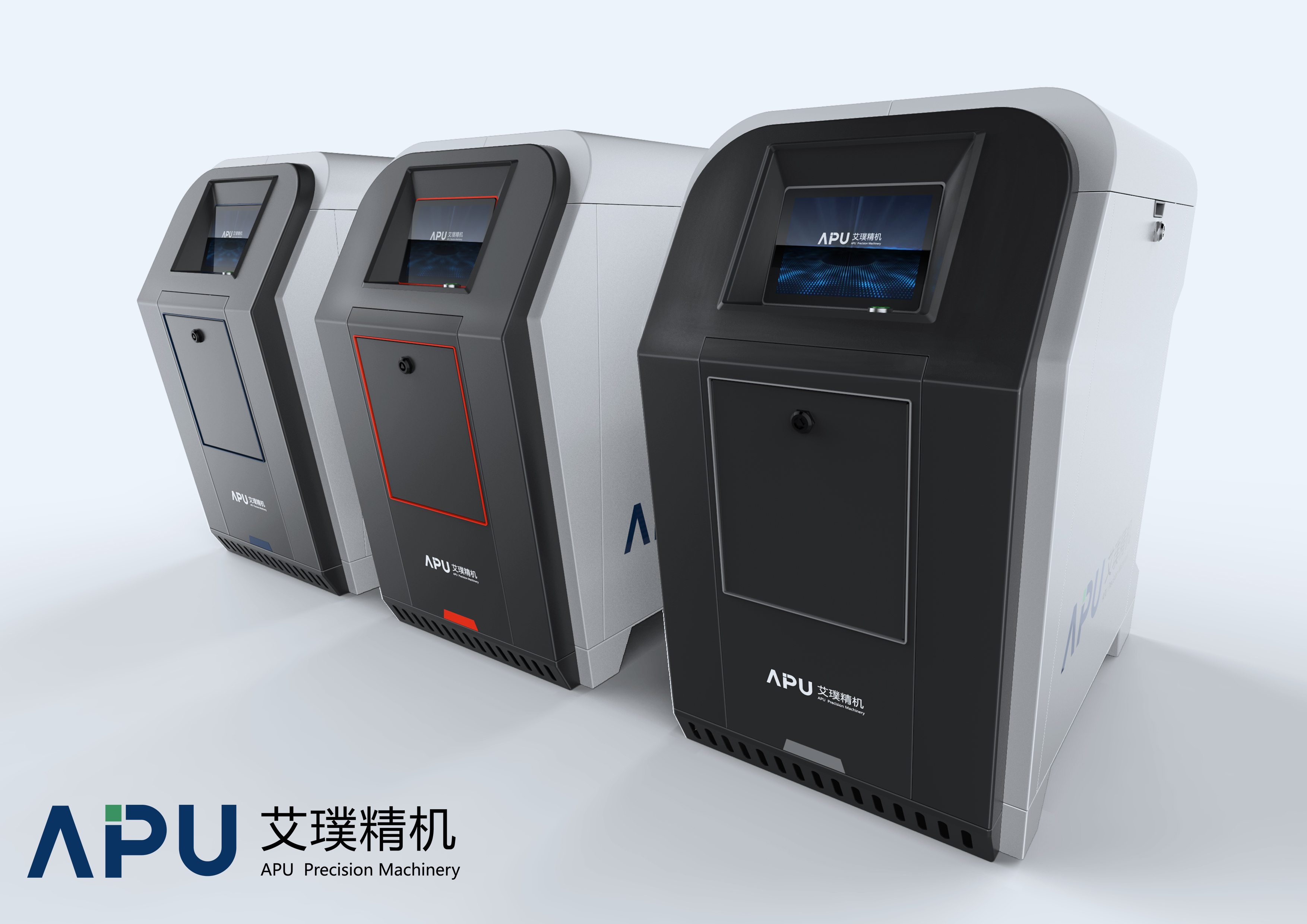

The air compressor designed for a precision machine is a design just after graduation. It has insufficient experience. Now there are many areas for improvement.

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

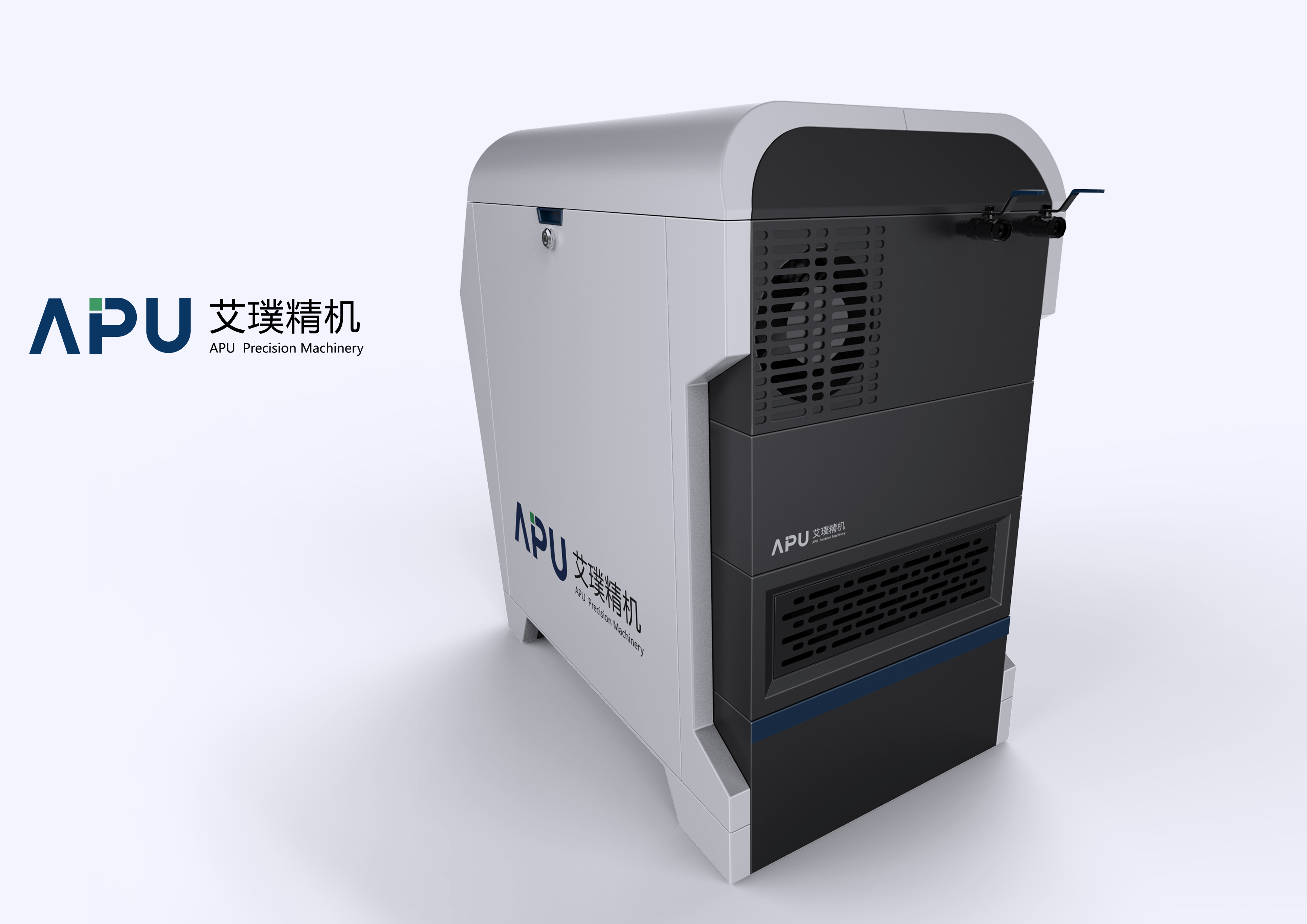

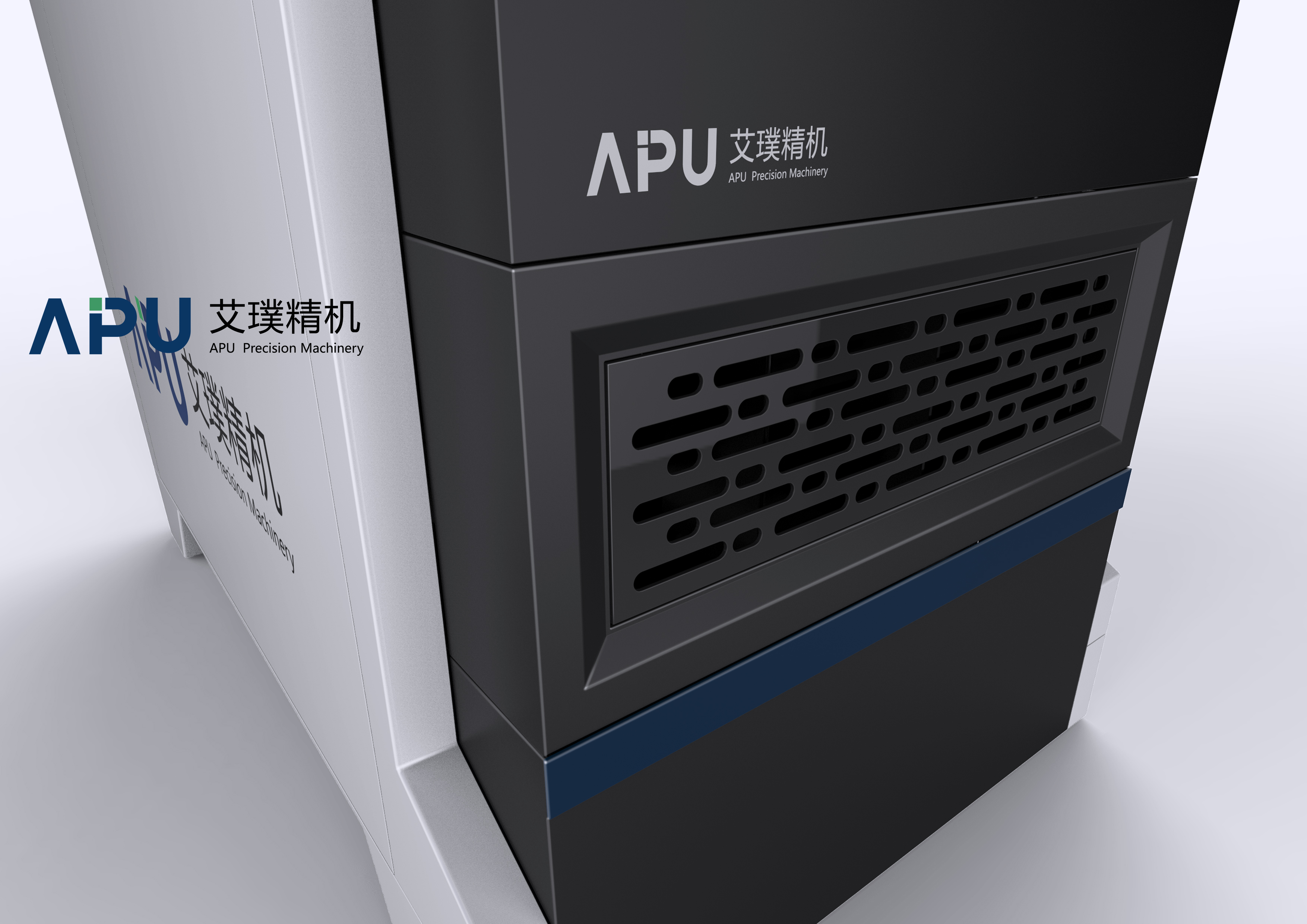

Blogger, ask what kind of structure type this screw installation method is without exposure, and several pieces on the side should be sheet metal type, how to ensure the neatness and flatness of the joints, please communicate

Plastic shells can still be done

The arc above should not be possible

Can the landlord have any experience in sheet metal products? Graduation received a similar task a little unable to start

You don't have this production, do you?

To do rapid prototyping 3D printing contact Mr. Mou 13957628446

Great!