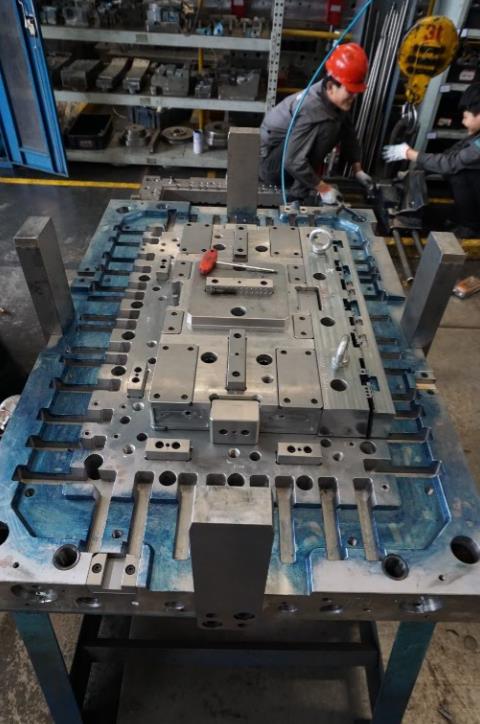

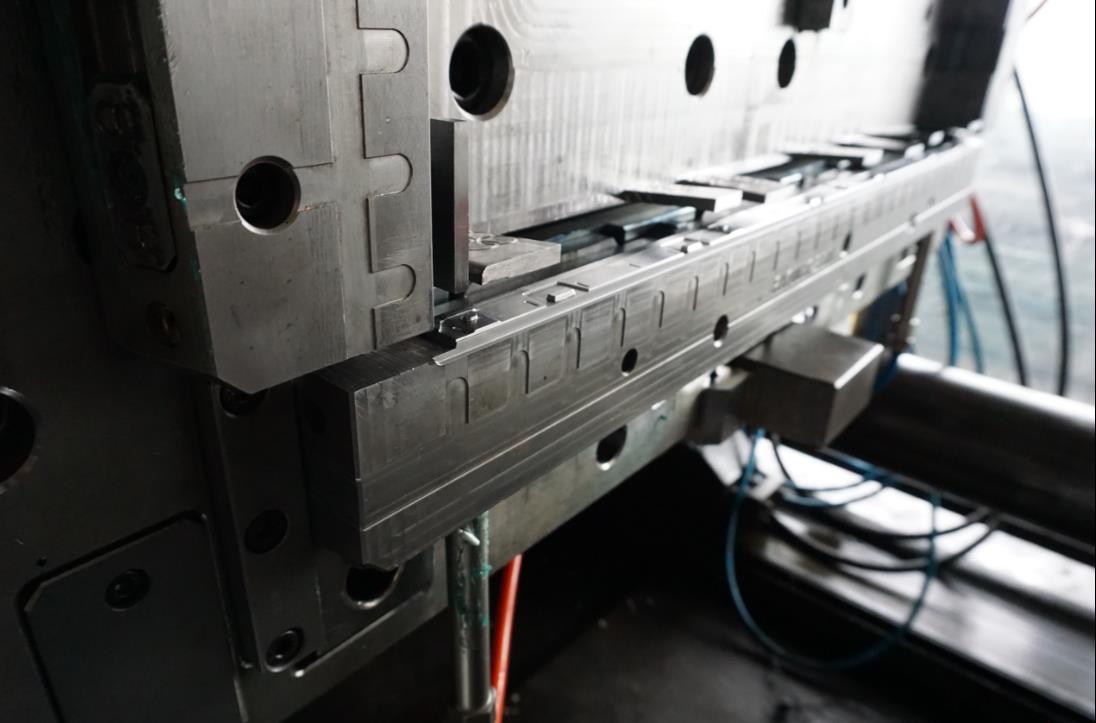

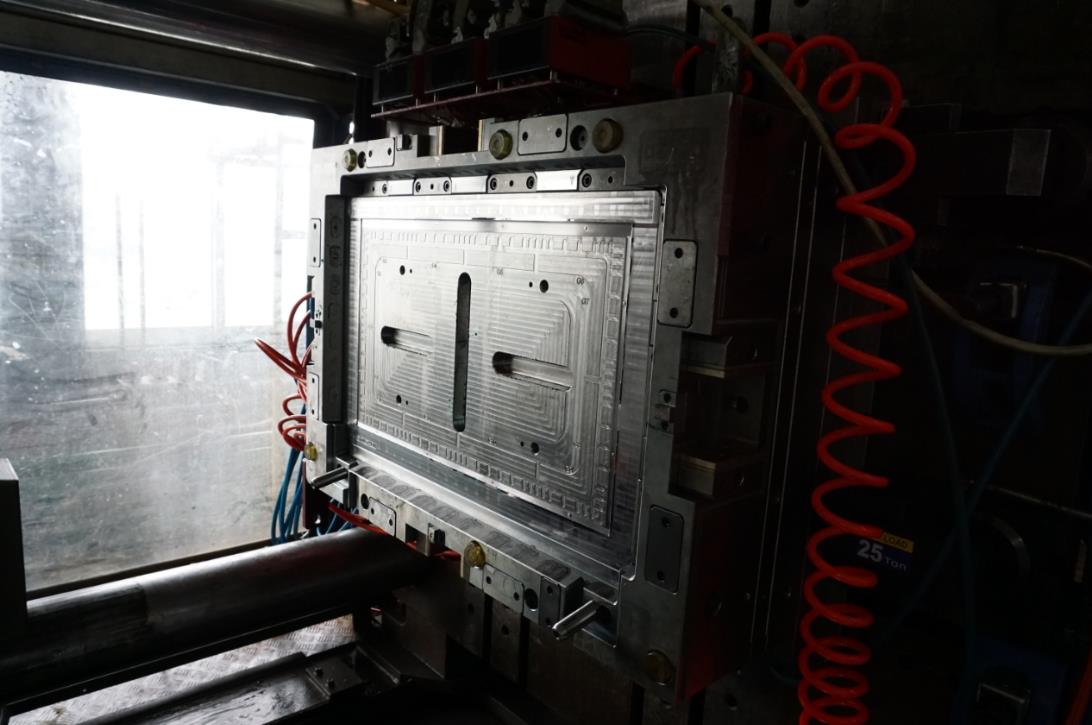

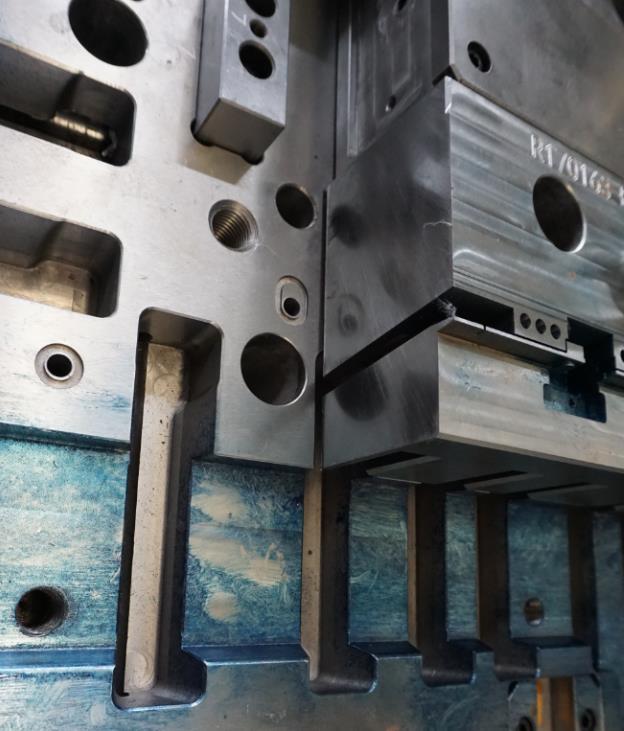

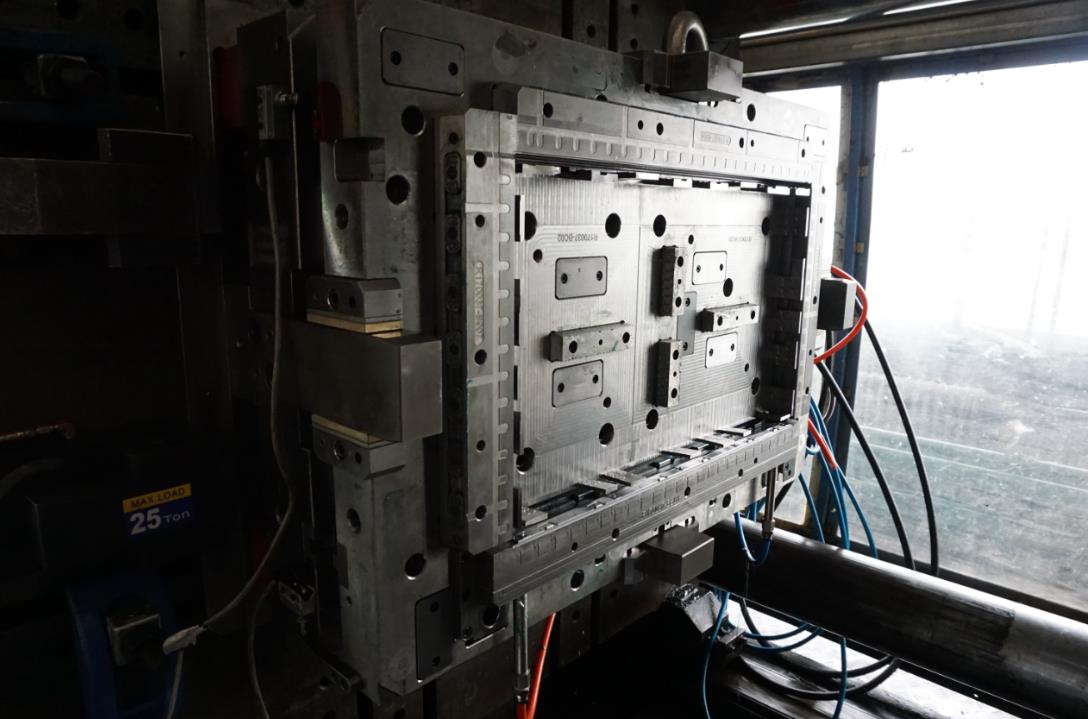

The work adopts a new inclined top structure, which is mainly composed of oil cylinder, push plate, dial block and small inclined top. The push plate is fixedly connected with the dial block, and the push plate and the dial block are driven by the oil cylinder to drive the small inclined top to realize the ejector function. This structure is adopted to replace the original long inclined top structure, so that the length of the inclined ejector rod is reduced from 330-400mm to 100-120mm, the cross-sectional area of the inclined ejector rod is changed from (10-12)x(20-25)mm to (6-8)x(25-60)mm, and the ejection distance is reduced from 110-130mm to 40-60mm. The small inclined top structure can shorten the length of the inclined top by more than 70% compared with the traditional long inclined top structure, the strength of the cross-sectional size is also better, and the ejection distance is also significantly shortened, which can greatly reduce the risk of inclined top fracture and improve the reliability of high mold mass production. At the same time, reduce the thickness of the mold and reduce the cost of the mold material. At the same time, the mold also applies rapid cooling and rapid heating technology, so as to realize the high-gloss effect of the product without spraying, omit the later spraying link, avoid environmental pollution, and make Qingdao Hisense Electric Co., Ltd., the first application, abolish the original spraying line and realize real green production.

For details, please go to: http://successfuldesign.org/work/596ed3e2f33fd5254932b22a

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

留言板 (0)

评论为空