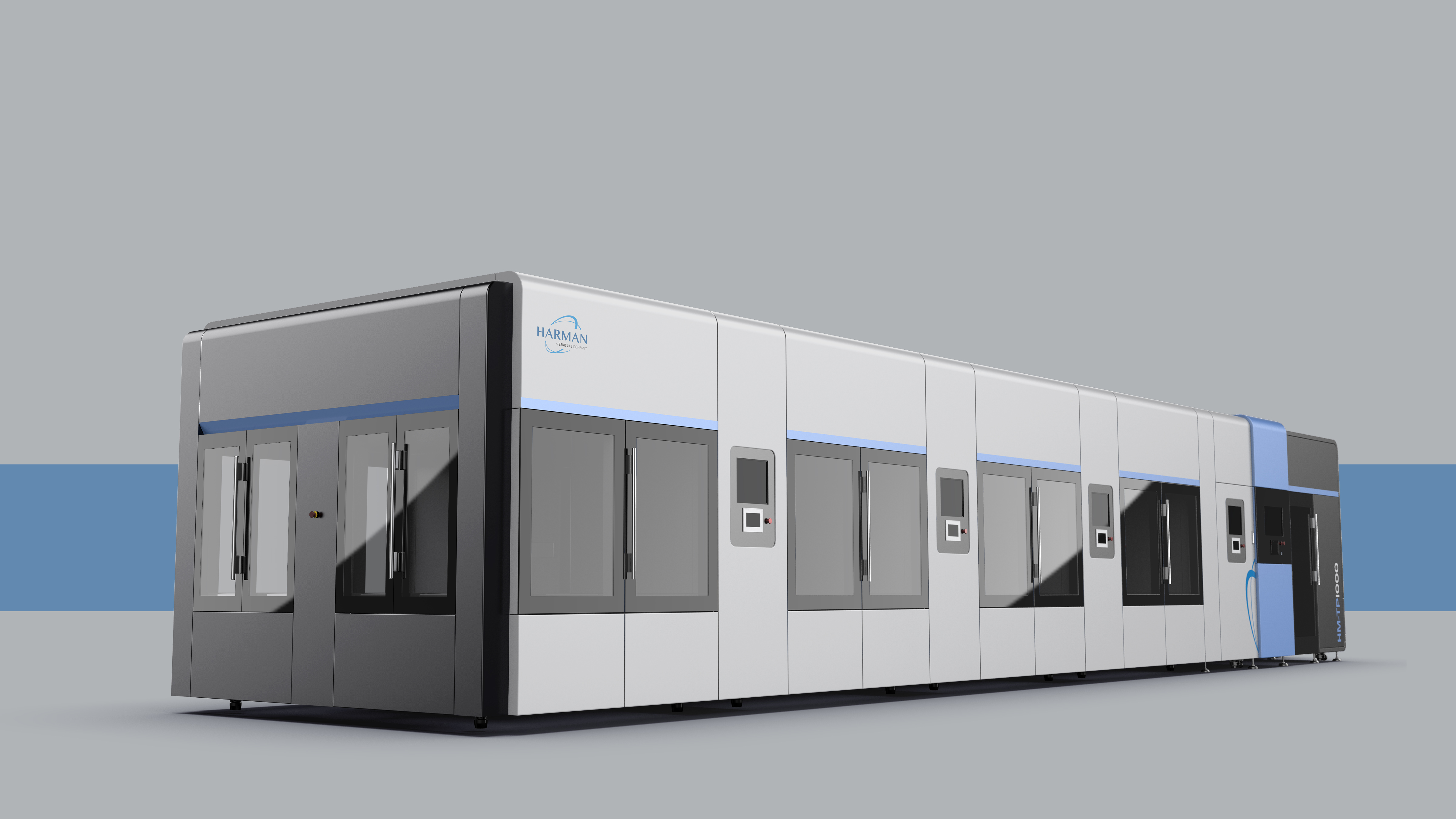

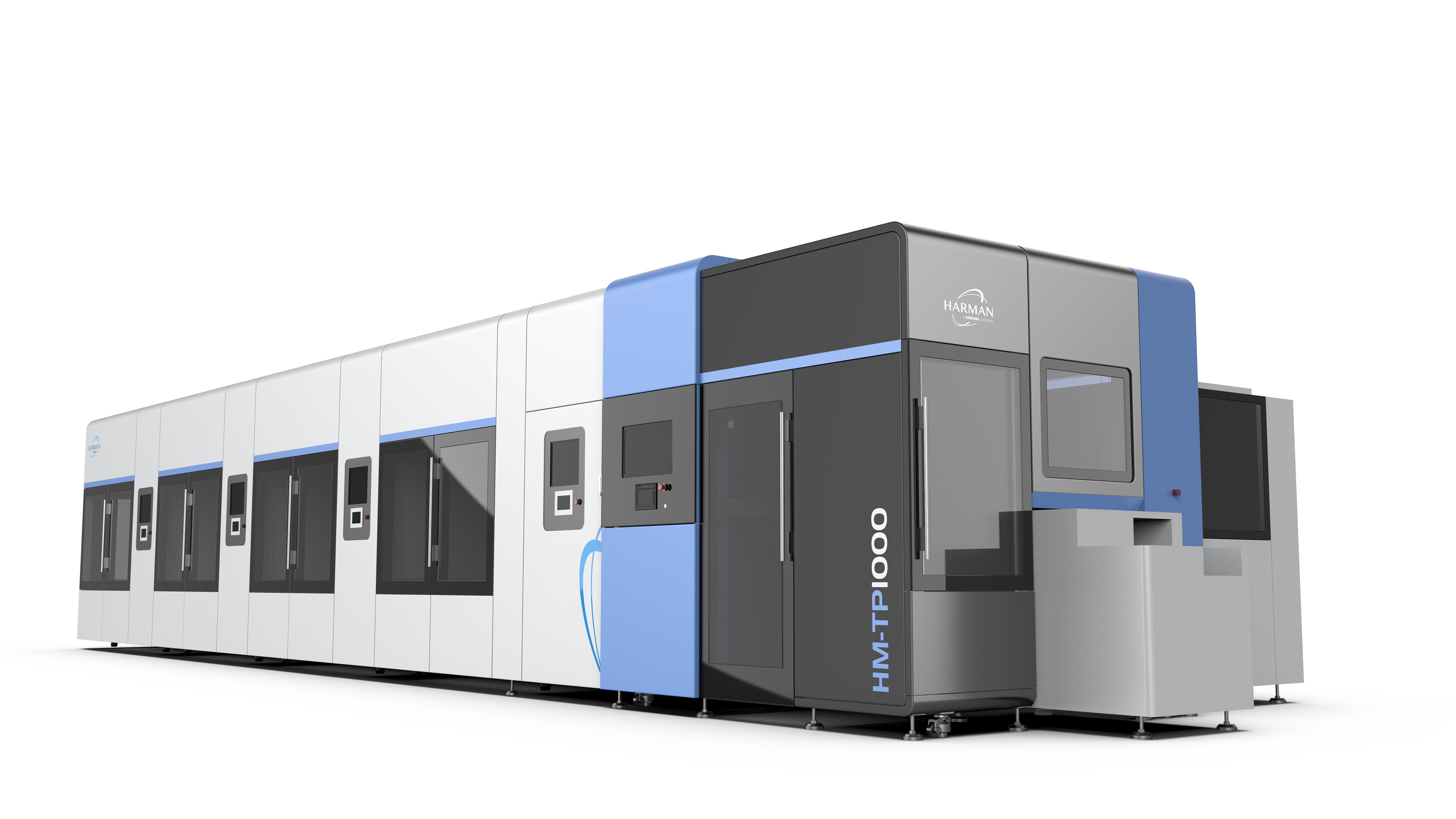

This is a production line designed for Harman. The overall design adopts design techniques such as wrapping and stacking.

Key Process--

Laser cutting: high precision hole, suitable for special-shaped contour.

CNC bending: the use of multi-tool sequence programming, to achieve complex bending (such as Z-shaped structure).

Riveting/pressure riveting: instead of welding, avoid deformation (such as nut column pressure riveting process).

Sheet Metal Design Material--

Cold rolled steel sheet (SPCC): low cost, suitable for internal structural parts (thickness 1.5mm).

Galvanized sheet (SECC): Anti-rust, used in humid environments.

Aluminum alloy (6061-T6): Lightweight, corrosion resistant, locally applicable.

本作品版权归 WOO 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

Too strong

nice

Professional ah

It's not easy

Perfect