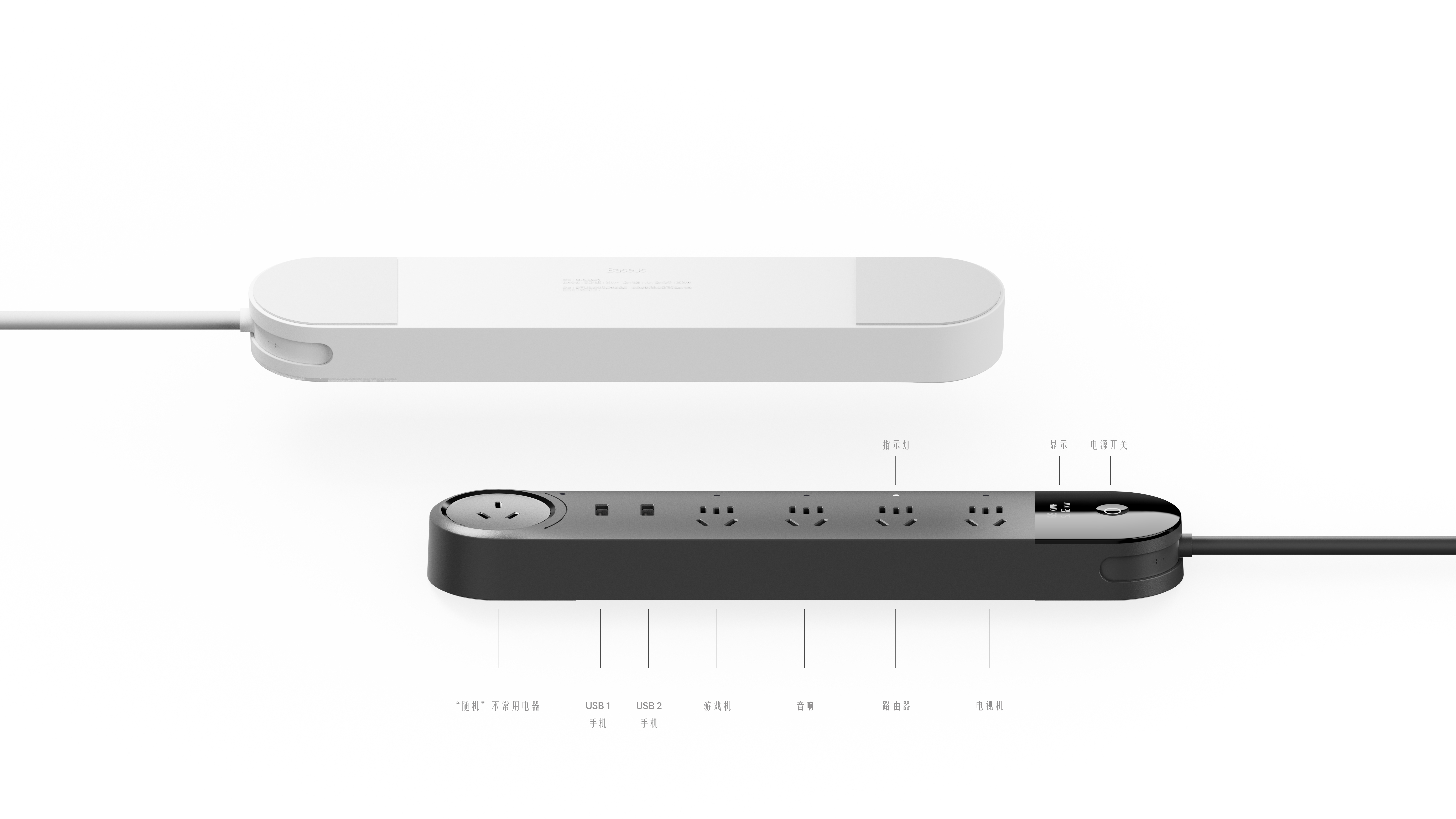

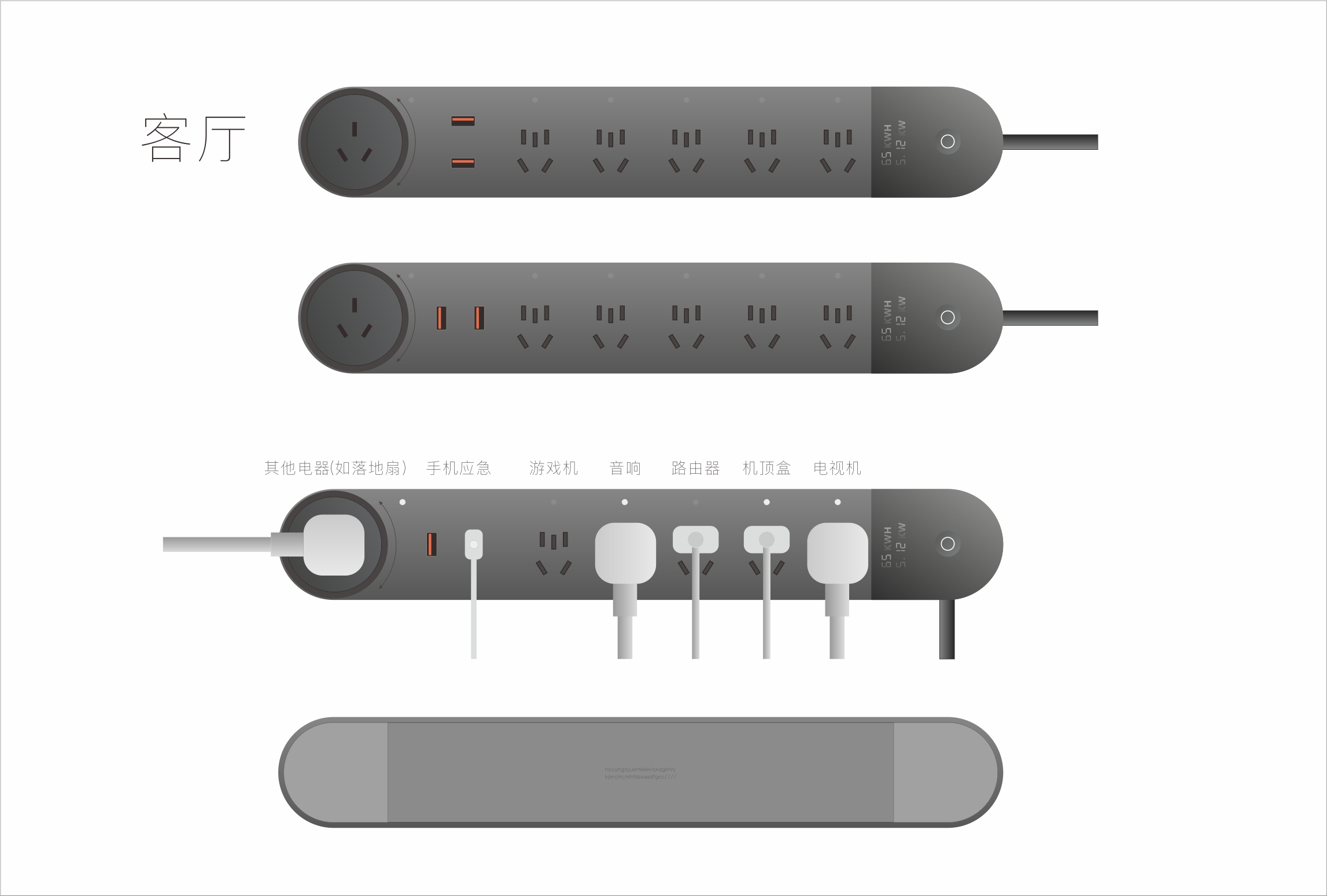

I tried to define a family plug-in. Two years ago, the company wanted to take it out and have a look. If you don't like it, don't spray it and have fun.

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

It's pretty good, but it's hard for structural engineers

The surface cannot be made into an arc surface. There must be a plane. The socket plane and the plug plane must fit together. At present, no arc surface is found on the plug. Otherwise, it does not meet the anti-electric shock experimental standard. It is also visually insecure. It always feels that it is not inserted in place. Refer to the upper surface of the upper shell of the millet socket. The design of the socket is very limited. There are several problems in the realization of this design. 1. The surface mechanism is scratched in use; 2. The internal wiring problem of the rear USB hole and the last jack, the design and the intersection of strong and weak current; 3. The cooperation between the internal rotation of the power cord and the switch needs to be studied. 4. The last jack needs to be rotated, and the internal connection will be a nightmare. 5. The hole spacing feels a bit large, there is the possibility of wasting space, which is related to material cost, mold cost and packaging cost. 6. The surface identification is missing. There are requirements for the surface identification content in the standard. Although it is added in the later design, it is an important content of design integrity. In the early stage of design, what process should be used to realize the identification content should be considered.

The effect is good.

Is it feasible to ask the arc surface of the insert row surface?

Why is the last three holes circular?

very fashionable

I usually like bulls.

good appearance