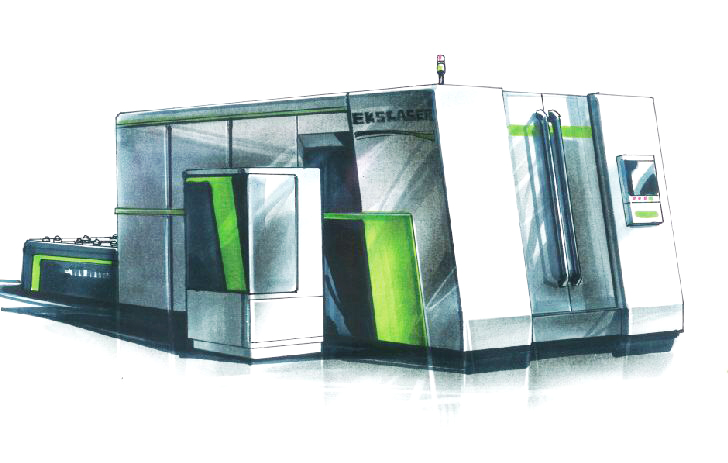

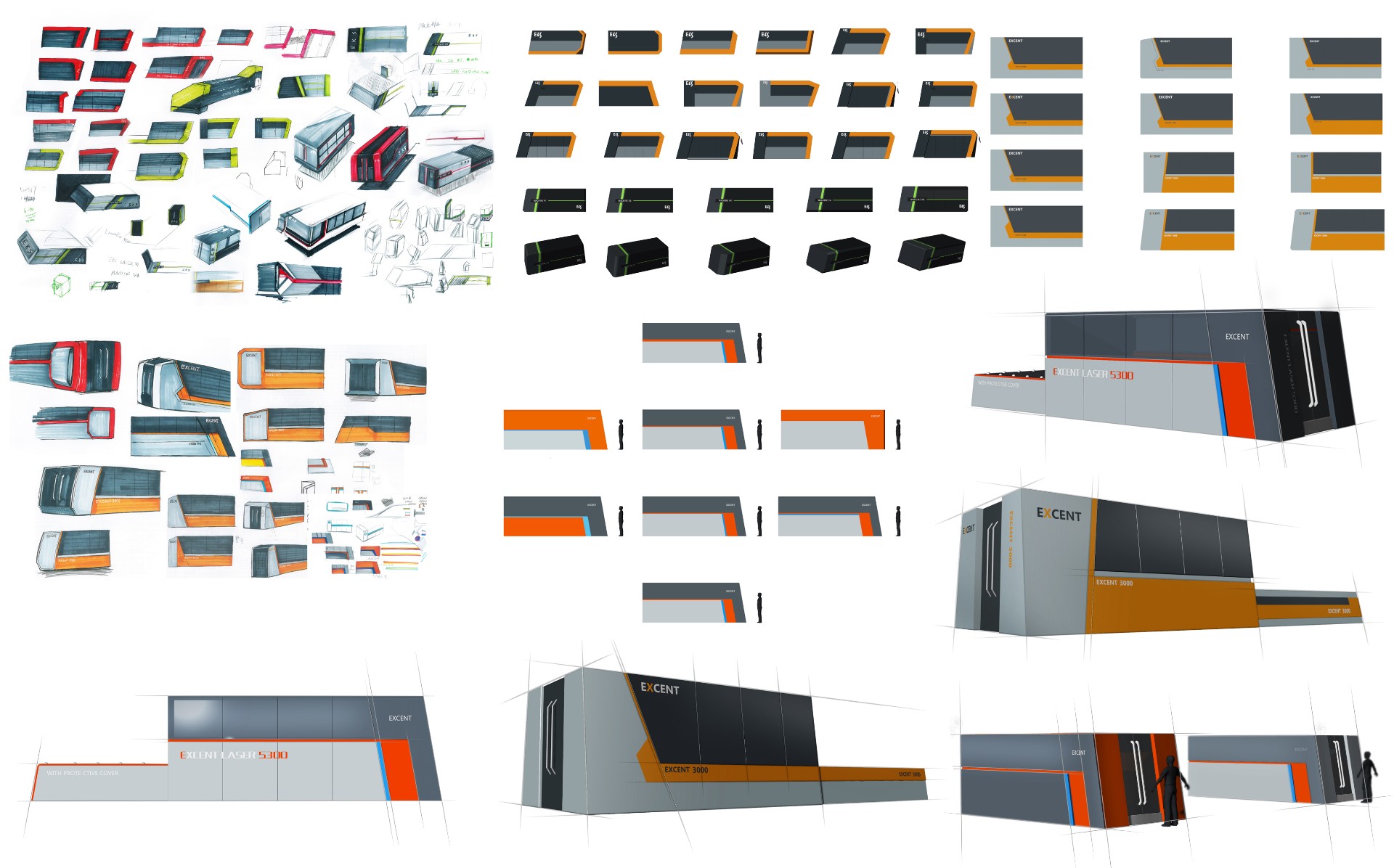

Original concept/First draft 2017

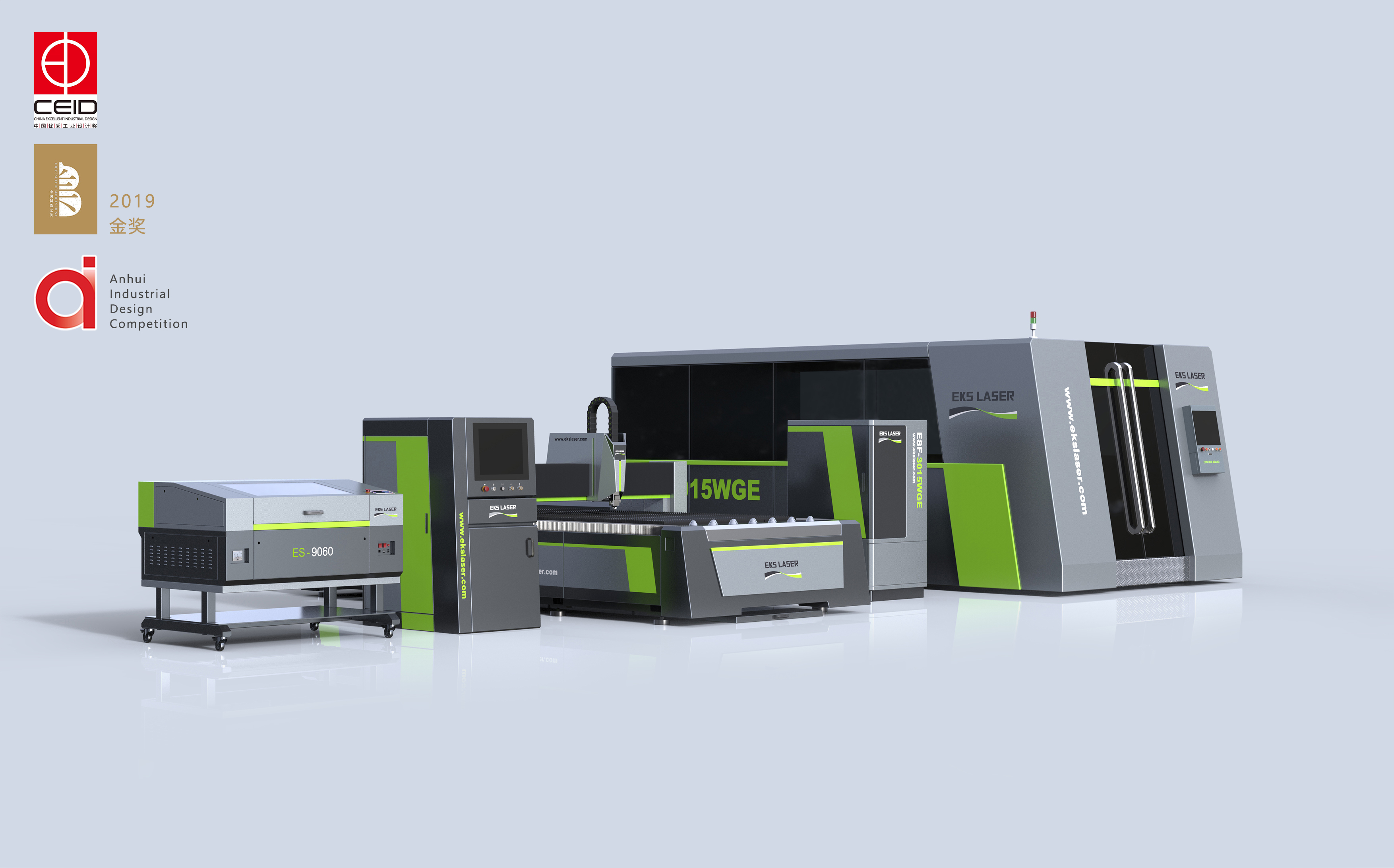

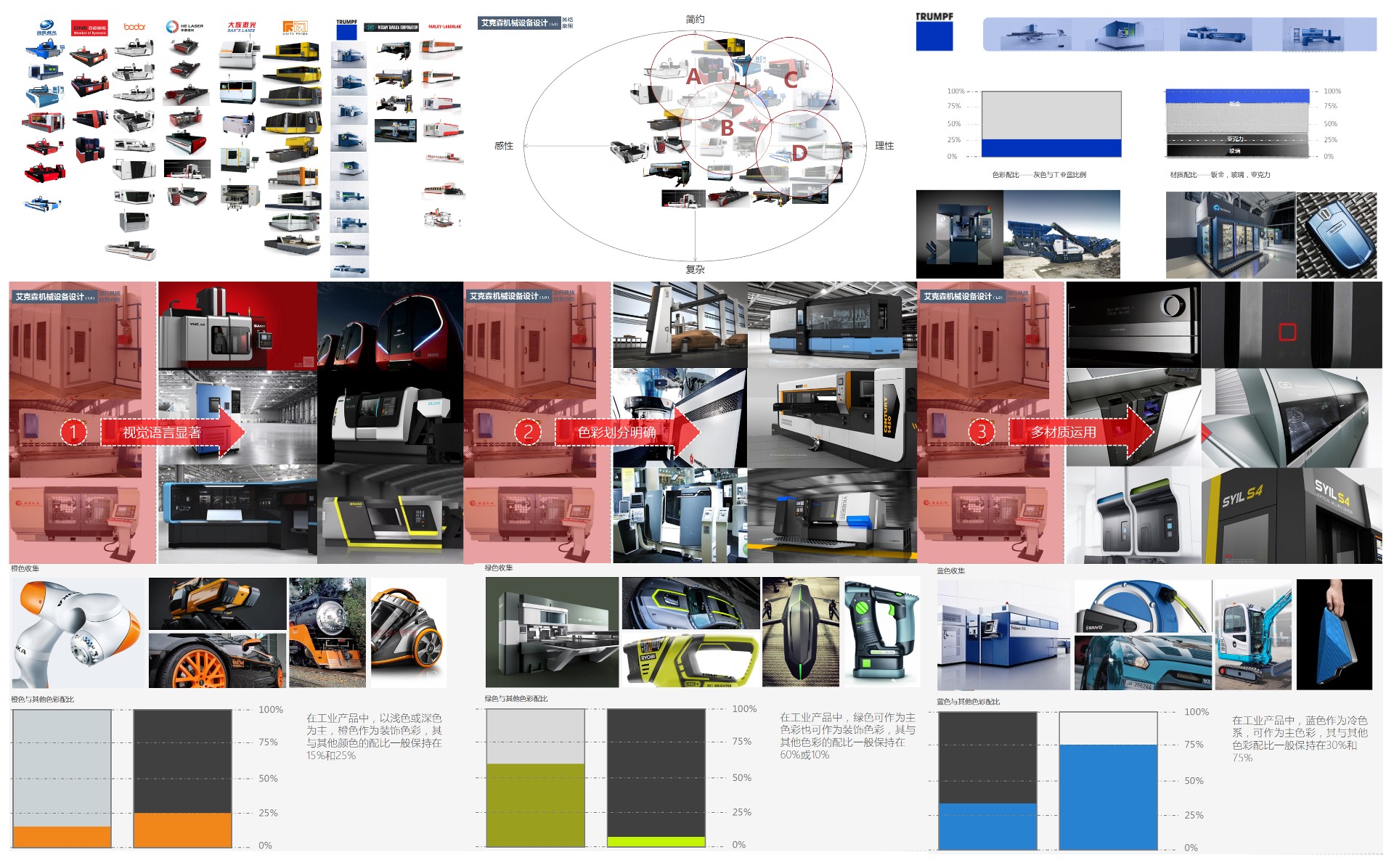

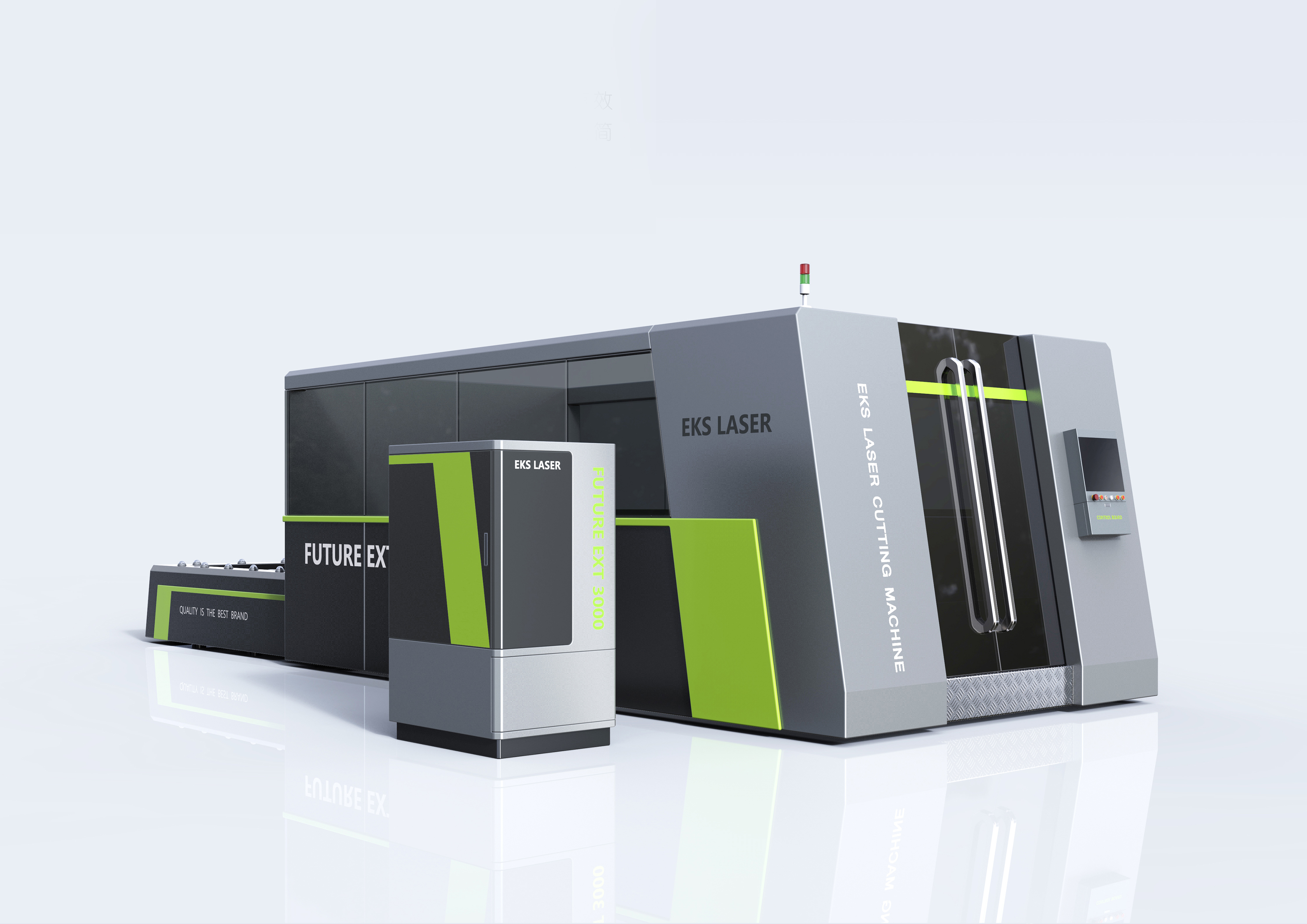

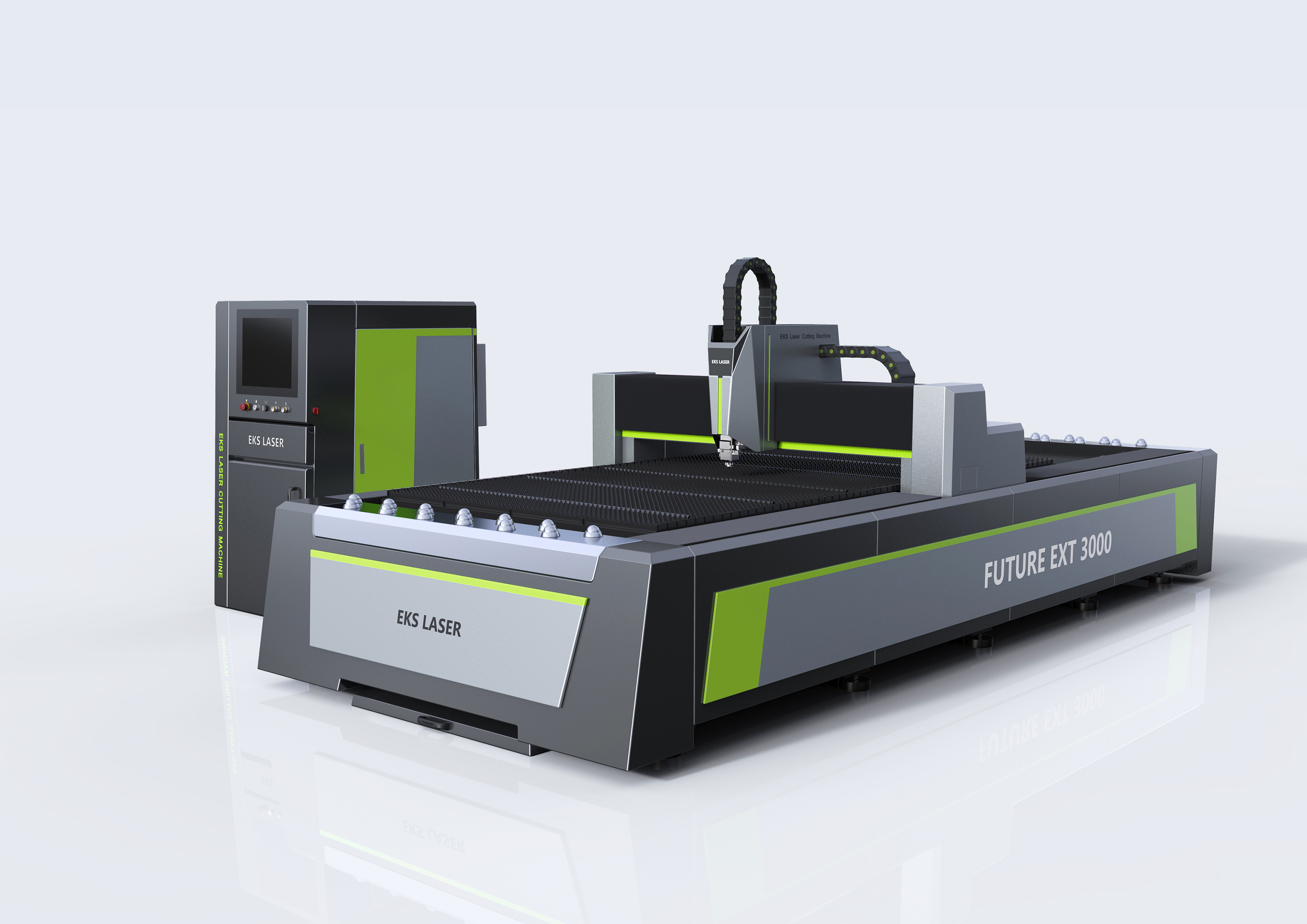

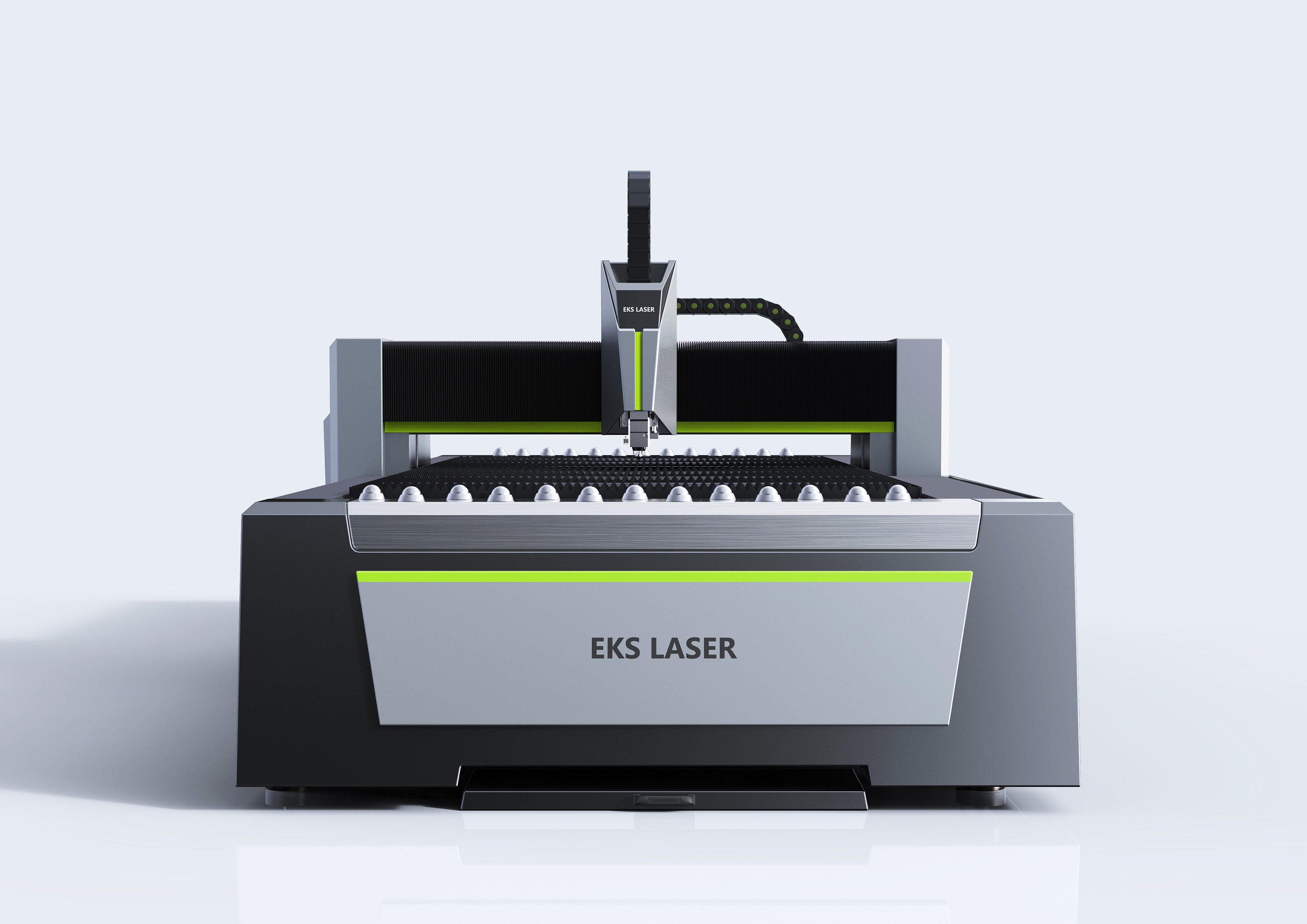

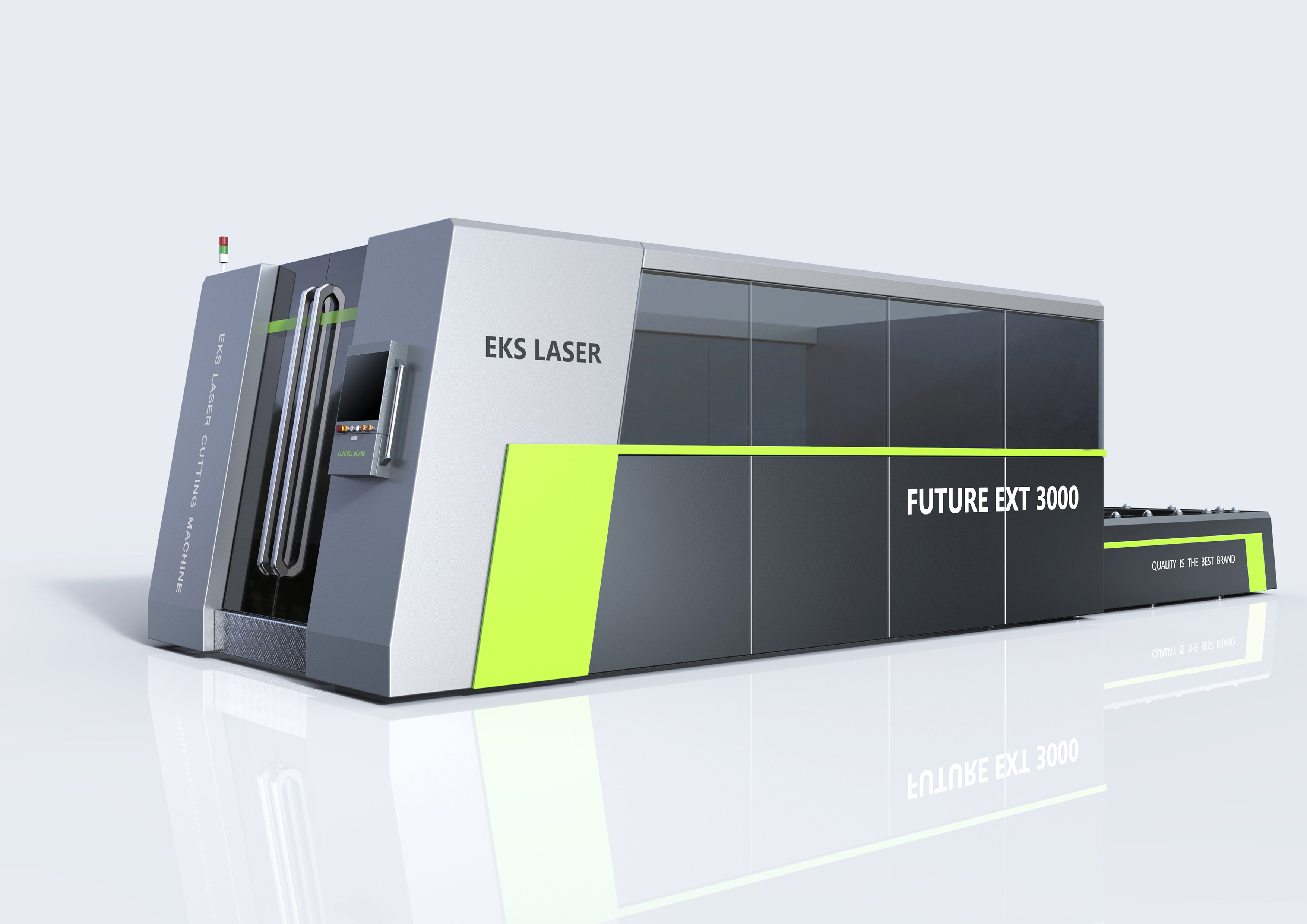

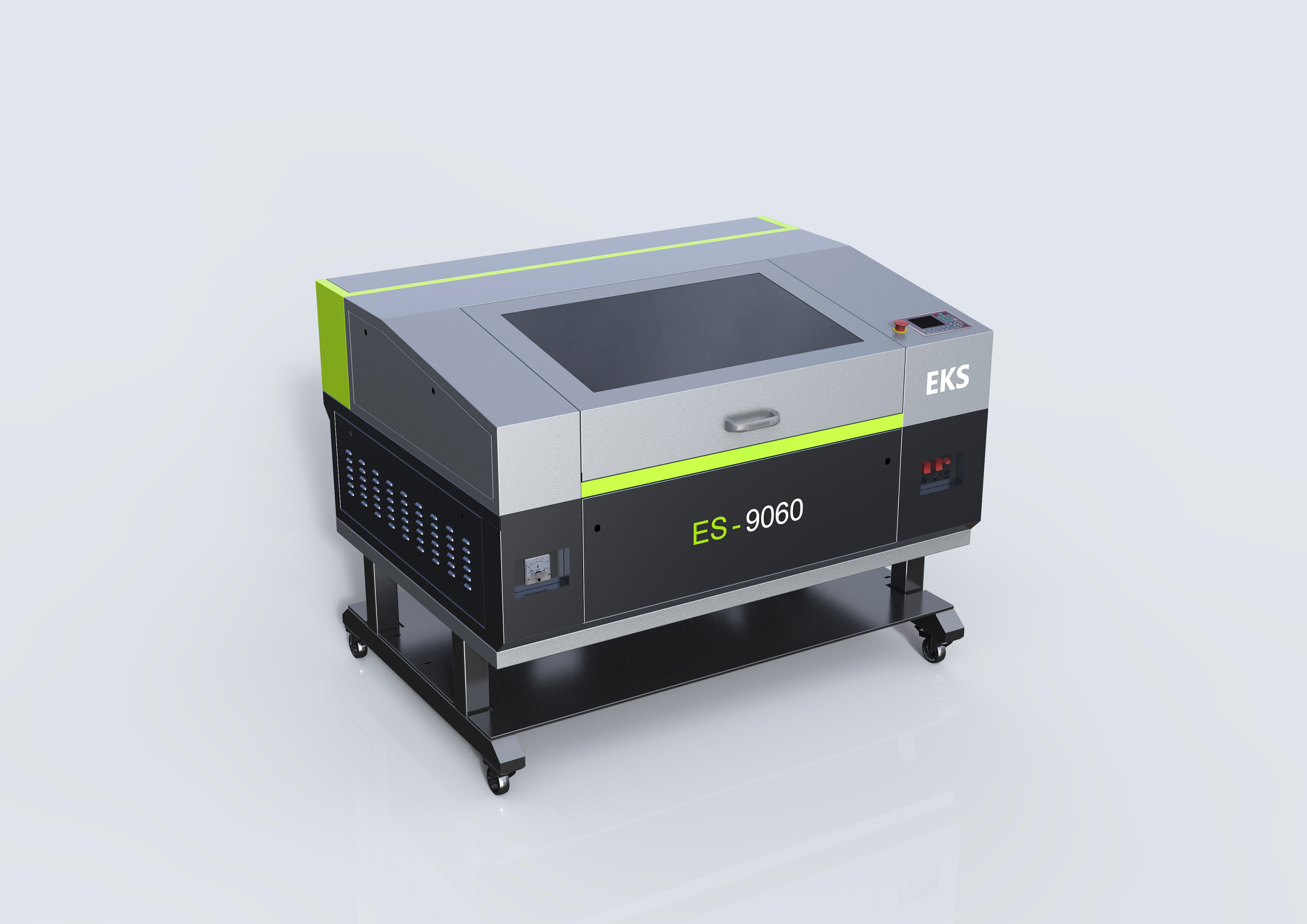

Exxon laser cutting equipment series, from small CO2 laser engraving machine, to medium-sized open dual-drive optical fiber cutting machine, to large-enclosed optical fiber cutting machine, are all available to meet various power and cutting requirements. At the same time, the series pays great attention to safety performance and has various protective measures. Among them, the open dual-drive optical fiber cutting machine is the smallest of the same category, effectively saving production space and transportation costs.

Welcome friends from all walks of life to communicate, the above is my WeChat QR code

本作品版权归 王子龙 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

I feel that the reduction degree of the landing scheme and the design scheme is quite high. Customers are willing to spend money to do it. Look at some equipment with four pieces on one side. If my customers will definitely say whether they can change it into one piece, the processing difficulty is too difficult to assemble, and the cost is a bit high... Ha ha the design scheme looks quite imposing and atmospheric.

I feel that the overall appearance of the first plan is better. The machine tool inside is normal. It is too capricious to use such a large blister. Ha, ha, ha, a little bloated. The second plan feels that the concave decorative parts will be more layered and the door body will be combined more skillfully. Also, the green color is too pink to hold down such a large equipment volume. The plan of the machine tool inside is OK, but the stainless steel in? personal opinion. after all, there are a lot of industrial equipment.

Major

The two-dimensional code style is somewhat against

Great!!