To share with the family a project that did not succeed in the early stage (draft stage);

Doing this project has enabled me to find a new design direction (extrusion molding and cutting) in this niche field. The process itself is not complicated, but there are few comprehensive applications in this front panel, and those who have different ideas can put forward them.

I have been in H3C, a major communication equipment factory, for three or four years before, and I still have a certain understanding of the panel design of several top manufacturers in the industry, including (familiar IBM/Cisco/HUAWEI/DELL, etc.) the process is basically sheet metal plastic die casting.

In the early stage of this draft, I read the official websites of IBM/HPE/DELL/Guoxin/Anqing/Kunqian/Huawei/ZTE/Lenovo/Great Wall/Zhongke Shuguang/Xinhua III/Langchao/Memory/Huaqing/Renbao/UNPROFOR/Ning Chang/Ziguang Computer/Xiangjiang Kunpeng/Yunjian/Xinwei Stock/BYD/Baode/Radio and Television Wuzhou/Changjiang Computing/Cisco/Fujitsu/Cisco/Baixin, etc, it is found that the front panel design and manufacturing level of some small factories in China is very limited, or there is no, or the design update is relatively slow. (The cost of updating once is not small)

However, this design object is mainly extrusion molding! (Very interesting is a thing)

Since my design is basically a person's workflow, many design processes or ideas are basically in my mind or on white paper to make a schematic diagram, or look at other diagrams and shift flowers to my plan ~.~

The following design scheme is only in the form of detailed design in the early stage.

Welcome to exchange.

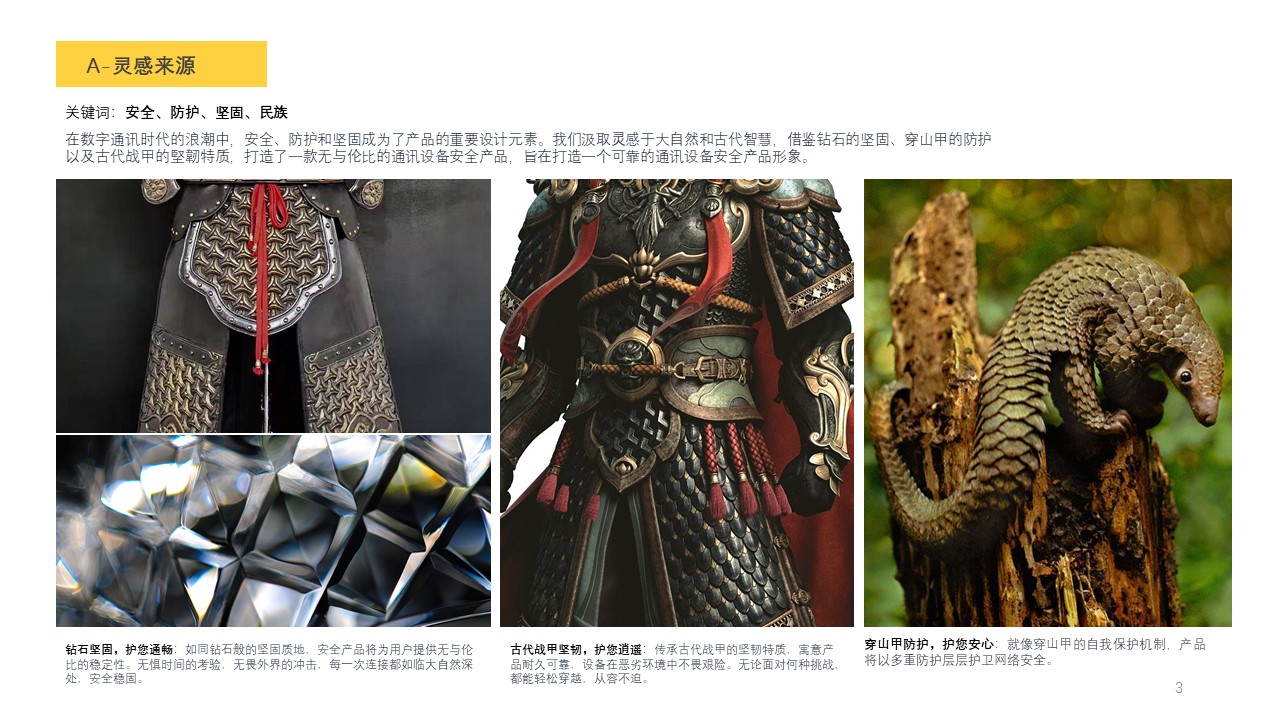

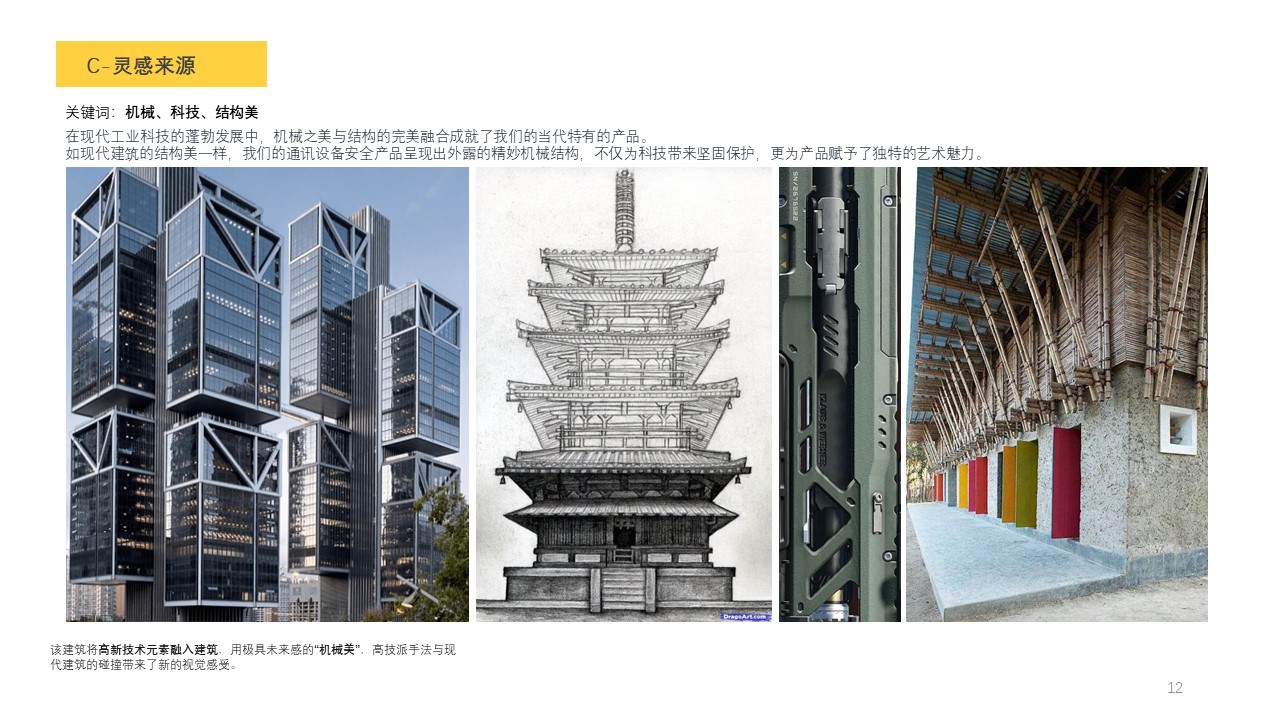

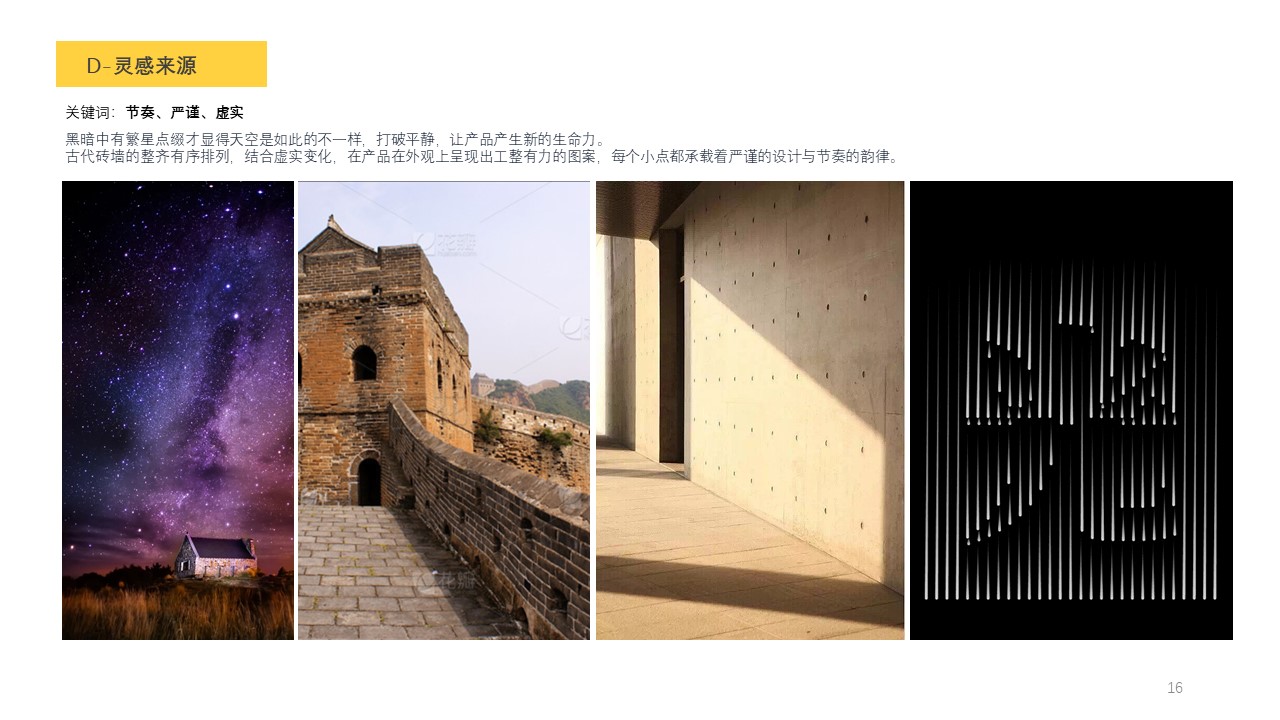

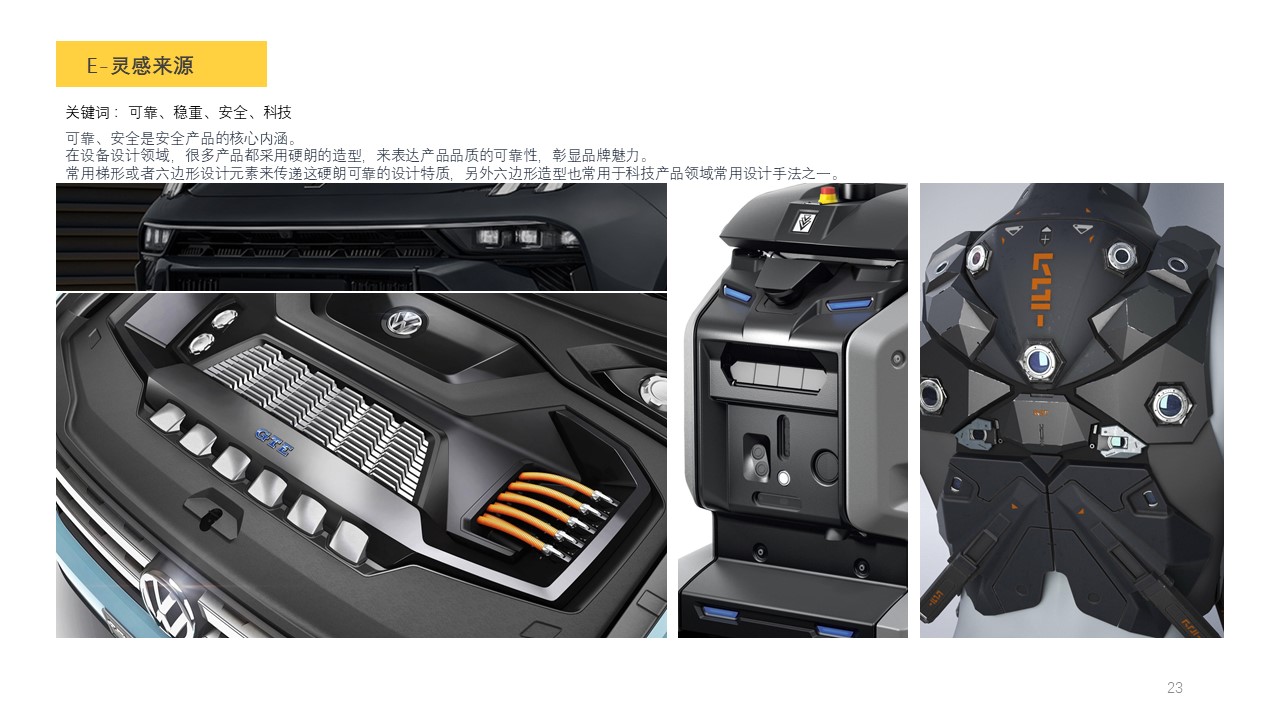

First, put some useful or interesting peer and non-peer product maps on the inspiration version. These maps can have certain reference value for your later design.

Non-peer design drawings, more I care about the form of heat dissipation holes or the structure of the panel.

Personally, I am more interested in the expression of form.

This is just a part of the content.

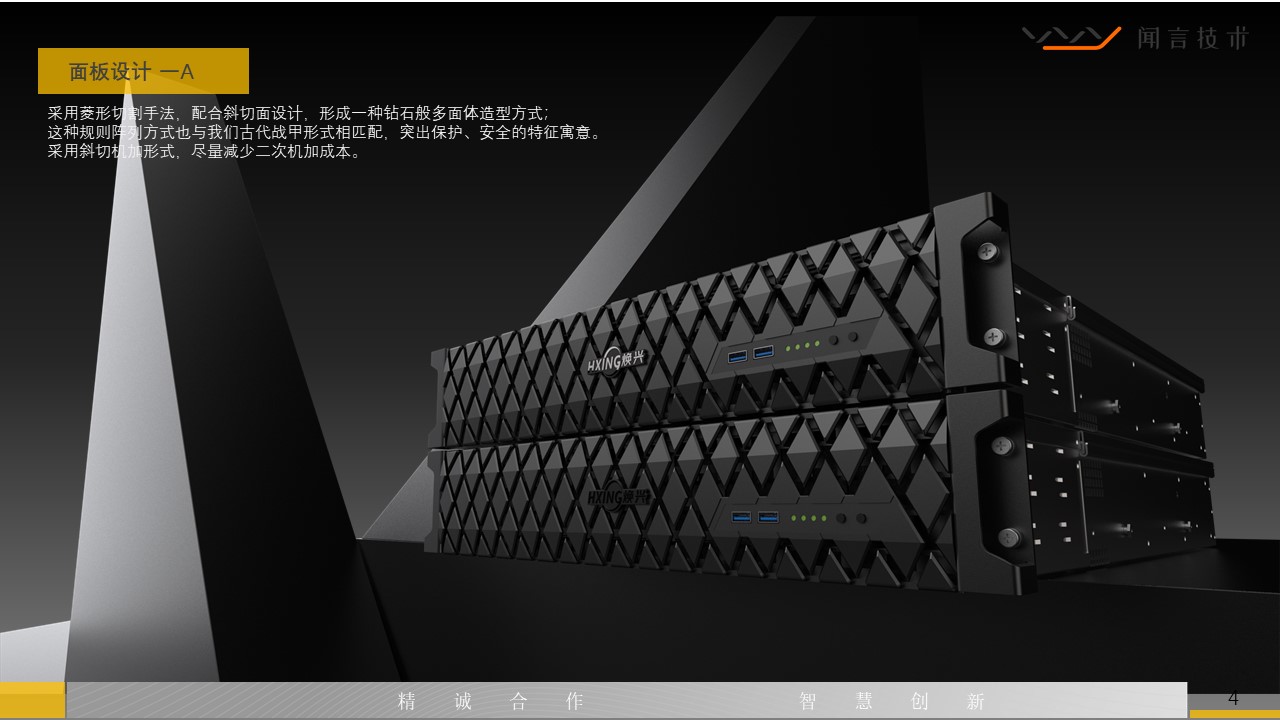

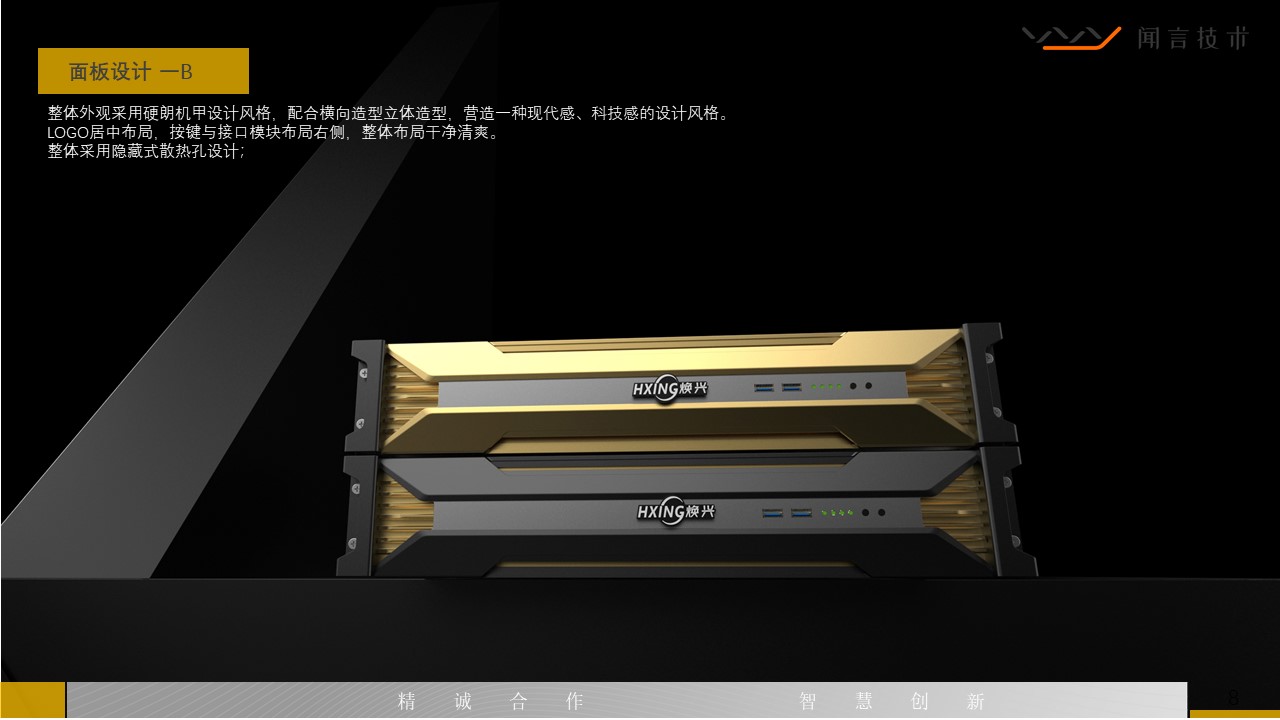

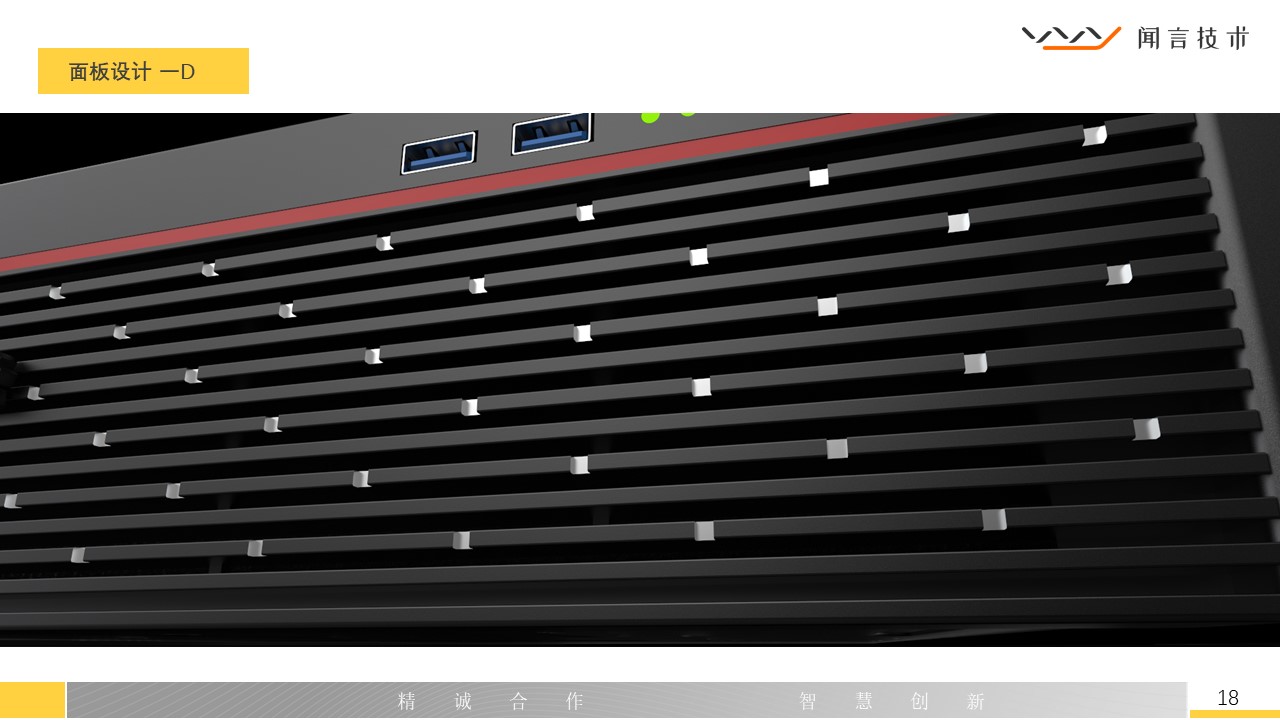

These designs are considered extrusion molding machine plus. For example, it should be completed in a three-axis or four-axis machining center, and it should not take too much processing time.

This is two layers, the bottom has become the upper layer, can also be extruded at a time, can also be split extrusion.

It took a lot of time to figure out how to implement this assembly method for the front panel interface part.

本作品版权归 一束光产品设计 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

Do you have five plans for one person?

The design is awesome, with a mechanical product style, but I didn't figure out how he realized the first plan A. Is each piece independent? That's quite a test of manual assembly. If it is a whole, but it looks like it is suspended inside, how is it processed?

Thinking from inspiration alone is a great idea, especially Scheme A. However, from the company's point of view, the cost of die-casting schemes is very high, especially the processing plant heats one-time die-casting molds, and a batch of die-casting raw materials are basically 500 to 1000kg. However, the sales volume of such chassis is generally not very large, and small and medium-sized companies are unwilling to stock up, thus failing to meet the requirements of suppliers for die-casting quantity. Therefore, very small and medium-sized companies choose relatively common profile plates for processing design or direct sheet metal folding welding process, with relatively low cost. Or like scheme d, there is an empty area, which can share the basic panel, mill holes in the later period, meet a variety of product layouts, and the cost can be controlled. it is the scheme considered by the company.

Very good design, suddenly was bosses through the Ren Du two pulse

A person's workflow is very strong.

666

good design