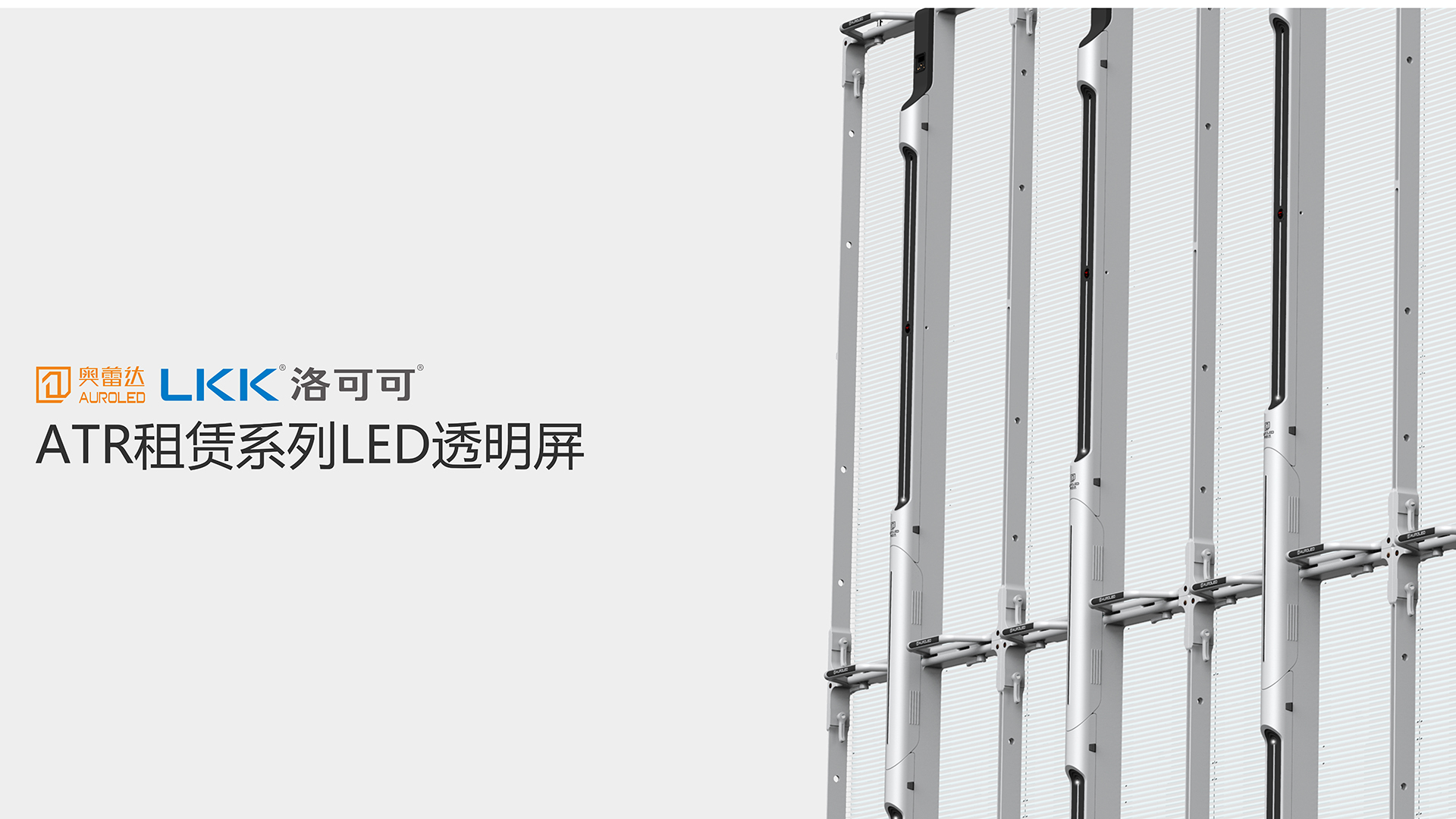

Project background: At present, the problem of leasing LED screen mainly lies in the clutter and variety of connecting lines. The structural frame is thick, which affects the weight of the whole machine and the permeability of the transparent screen.

User requirements: change the structure, die-casting one-piece box, reduce assembly steps, reduce a certain weight, and strengthen the stability of the structural frame. The modular line connection method can solve the problems of messy and untidy lines and increase the overall permeability of the transparent screen.

Product strategy: Modular line connection mode can solve the problems of messy and untidy lines and increase the overall permeability of the transparent screen.

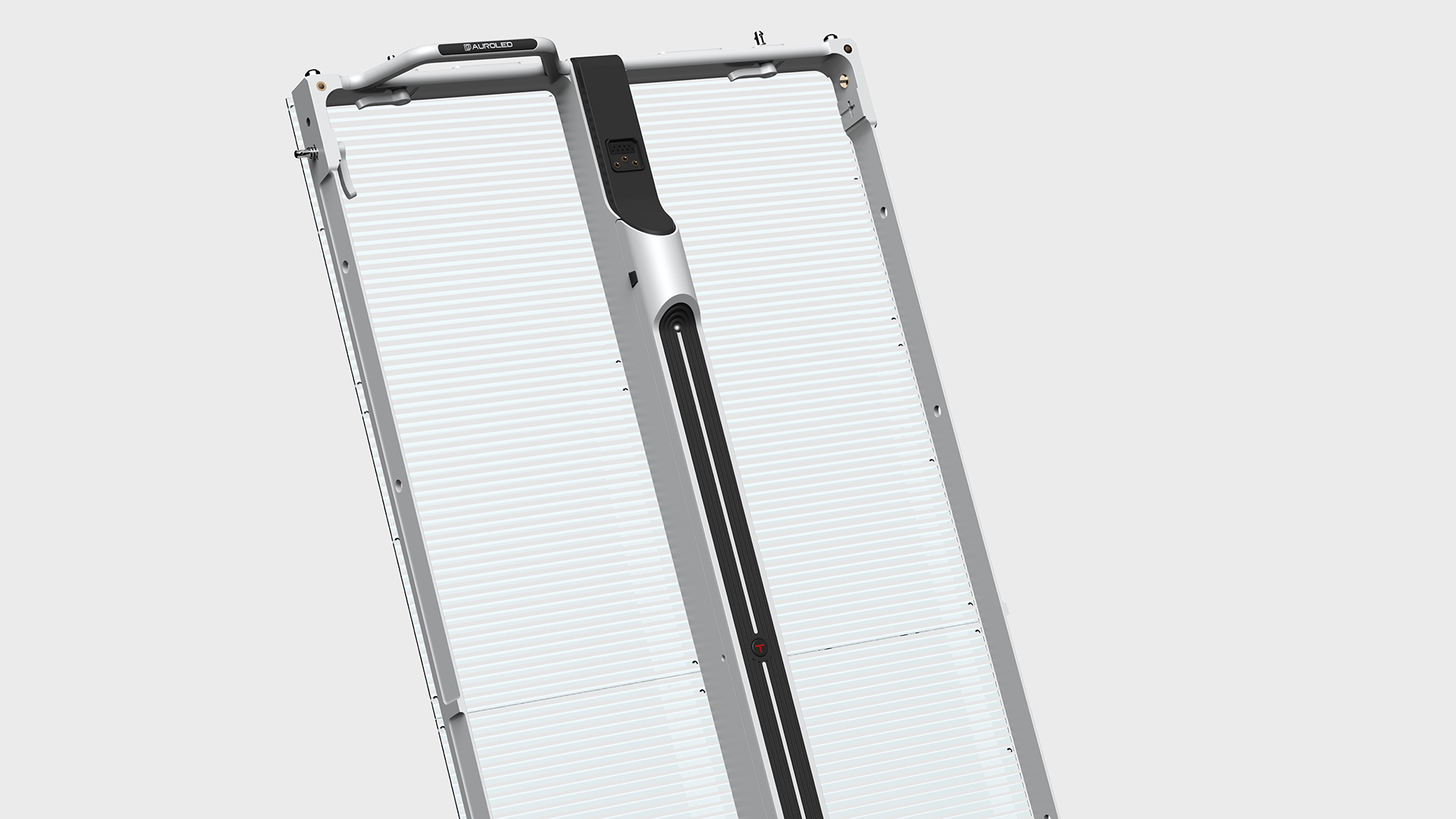

Optimization and upgrading: standardized 1000x 500mm aluminum alloy die-casting integrally formed box body, with firm and reliable strength and stable structural frame; Light and light experience, the whole box is only 8KG, which is only half the weight of conventional products with the same area. The thinnest thickness of the frame is only 4.8mm, which expands the transparency of the screen and reaches the ultra-high permeability of more than 90%.

Solution:

1. The power supply module adopts plug-in hard connection, which changes the original wired connection mode, reduces tedious steps, and realizes quick disassembly and assembly in 2 seconds, providing greater convenience for maintenance personnel and maintaining the cleanliness of the screen.

2. We take "crystal clear" as the design concept, simplify the design of product modeling, adopt simple geometric form as the visual center, weaken the surrounding functional structure, and adopt modular design to improve the complex process of splicing in one step.

本作品版权归 洛可可咨询设计 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

good design

Gao Da Shang