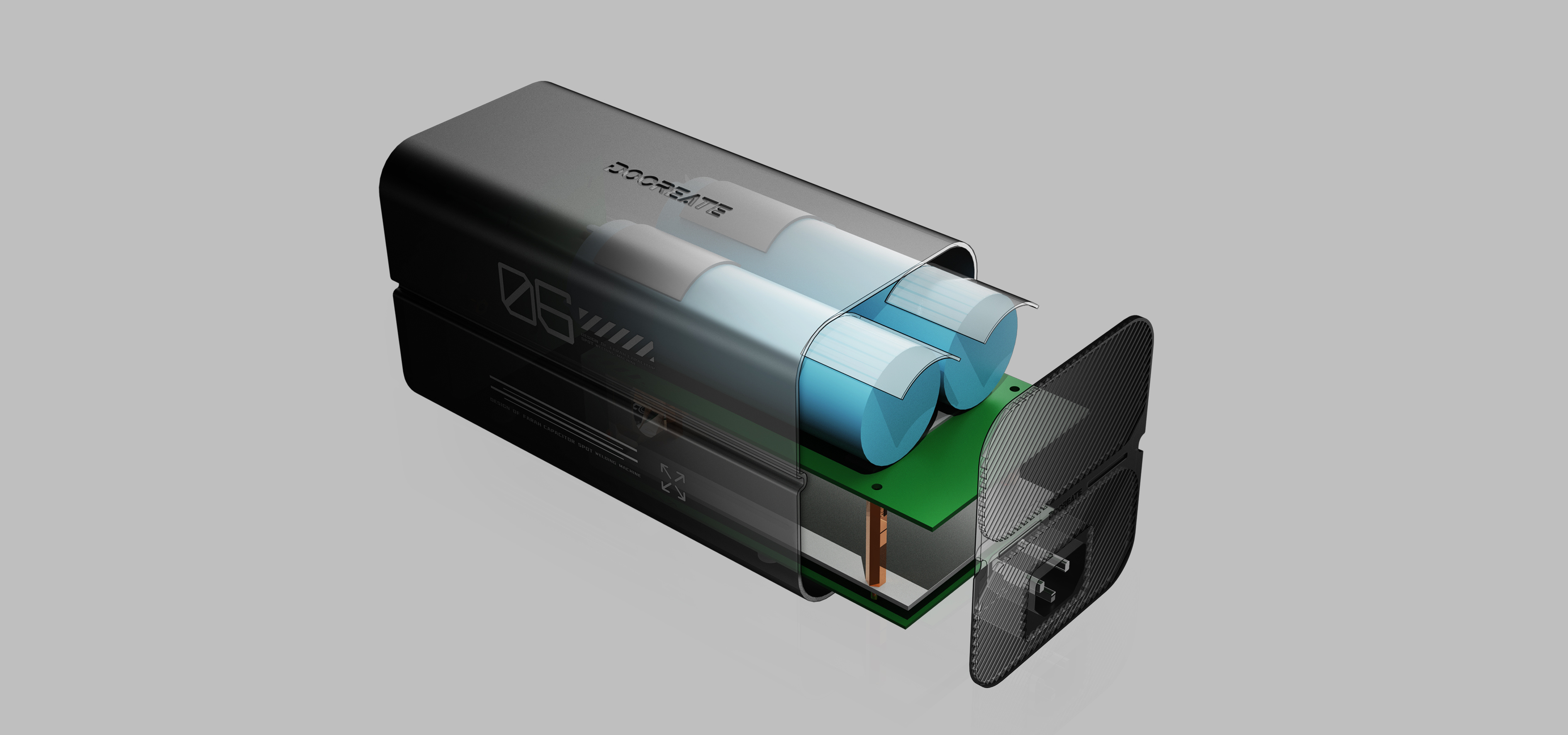

Farad capacitor welding machine, this is a very interesting and practical DIY or professional project, also known as capacitor energy storage welding machine, using the huge current released by the large-capacity Farad capacitor for welding.

Designing a farad capacitor welding machine is a comprehensive project involving power electronics, analog circuits, digital control and mechanical structure. For enthusiasts, you can start with a simple, fixed-energy version and gradually add advanced functions such as voltage control and digital display. For industrial applications, reliability, consistency and safety are important considerations.

Faraday capacitor welding machine, also known as capacitor discharge welding machine, is a very interesting and practical DIY or professional-grade project. It utilizes the instantaneous release of huge current from high-capacity faraday capacitors for welding

Designing a farad capacitor welding machine is a comprehensive project involving power electronics, analog circuits, digital control, and mechanical structures. For enthusiasts, they can start with a simple, fixed-energy version and gradually add advanced features such as voltage control and digital display. For industrial applications, reliability, consistency, and safety need to be considered as key factors.

Note: The copyright belongs to ZCKJ. This display is for communication only. It is forbidden to forward it without permission.

Designer: Qin

Time: 2024

Small impact on the grid: slow charging, will not cause the home trip.

· Accurate and controllable output energy: By controlling the charging voltage, highly consistent welding quality can be achieved.

· High instantaneous power: suitable for spot welding, impact welding and other processes.

No transformer: compared with the traditional frequency welding machine, the volume and weight can be made smaller.

· Long life: the cycle life of farad capacitors is much longer than that of batteries.

Capacitor selection: must use high current type or power type farad capacitor, ordinary farad capacitor can not withstand such a large instantaneous discharge current.

Capacitor selection: It is necessary to use high-current or power-type farad capacitors, as ordinary farad capacitors cannot withstand such a large instantaneous discharge current.

Use Scenario:

1. lithium battery assembly: welding 18650, 21700 and other batteries of nickel connection piece. This is the most widely used. 2. Electronic production: welding small metal parts, shielding cover, etc. 3. Laboratory and maintenance: used for precision welding of heat input sensitive components.

Usage scenario:

1. Lithium battery assembly: Welding nickel connectors for batteries such as 18650 and 21700, which is the most widely used application. 2. Electronic manufacturing: Welding small me-tal parts, shielding covers, etc. 3. Laboratory and maintenance: Used for precision welding of components sensitive to thermal in-put.

本作品版权归 秦 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

Nice, but the last girl has six fingers

The ratio of the last two pictures is too different. It looks a bit awkward. It is better if you can adjust it properly.

Long knowledge ah

Performance benchmark for professional scenarios

Subversion of the traditional technical logic

Brother, are your last two AI? not bad