Corrigan Modular Water Bottle | Product Appearance Design

2024-01-05

Home Appliance

10253

22

73

关注

私信

Super iron powder came to report

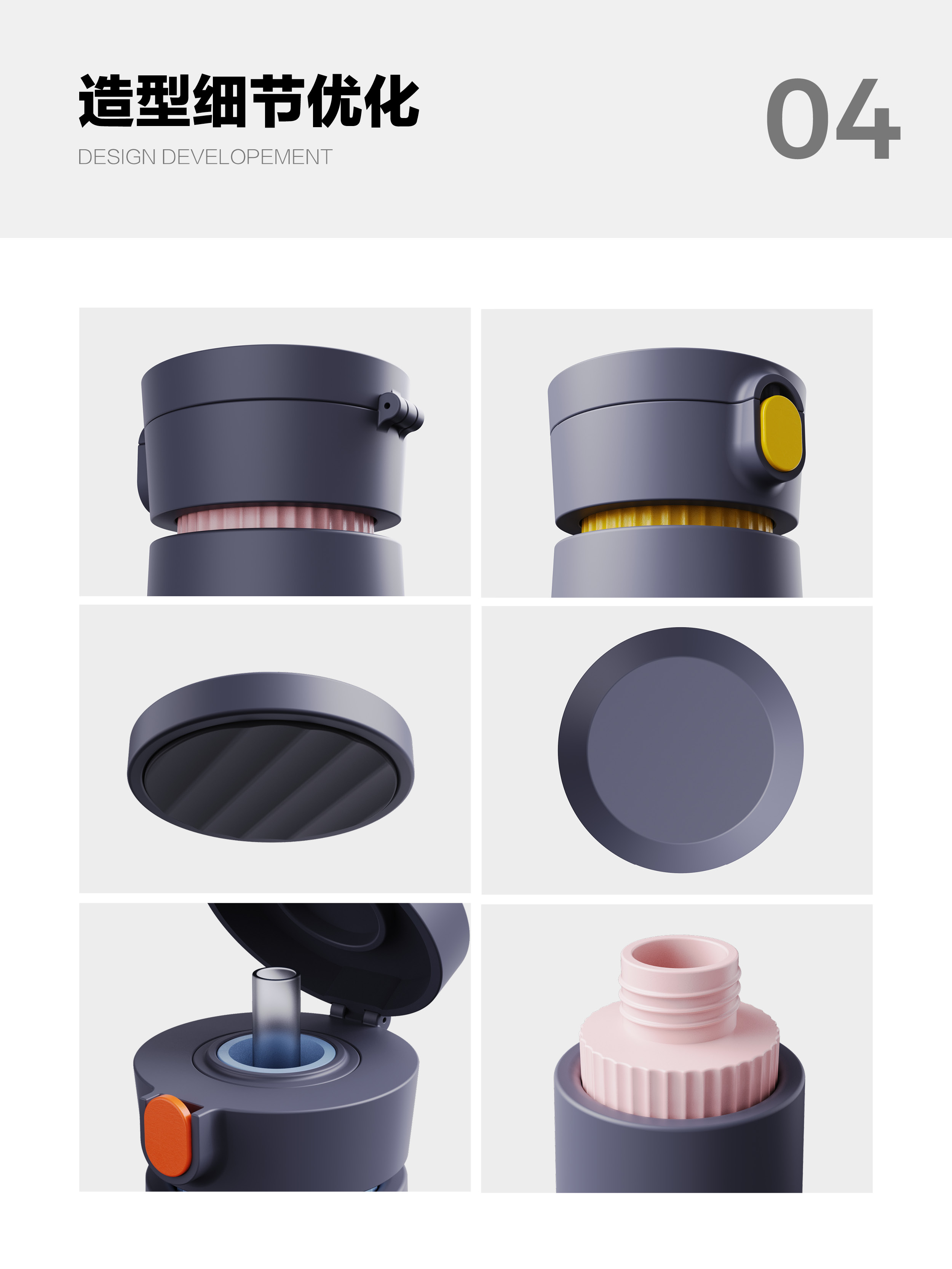

How to get out of the lid? If the wall thickness of the plastic parts is uneven, it is easy to shrink.

This little picture is really beautiful.

Support!!!

Several models can't be seen.

diaozhatian!

Big Brother is so strong

Too good.

Perfect

First-class design, first-class thinking, first-class rendering suit