Sogo Design... Ten years of focus on medical health the only track.

Cooperative customers: well-known confidential customers

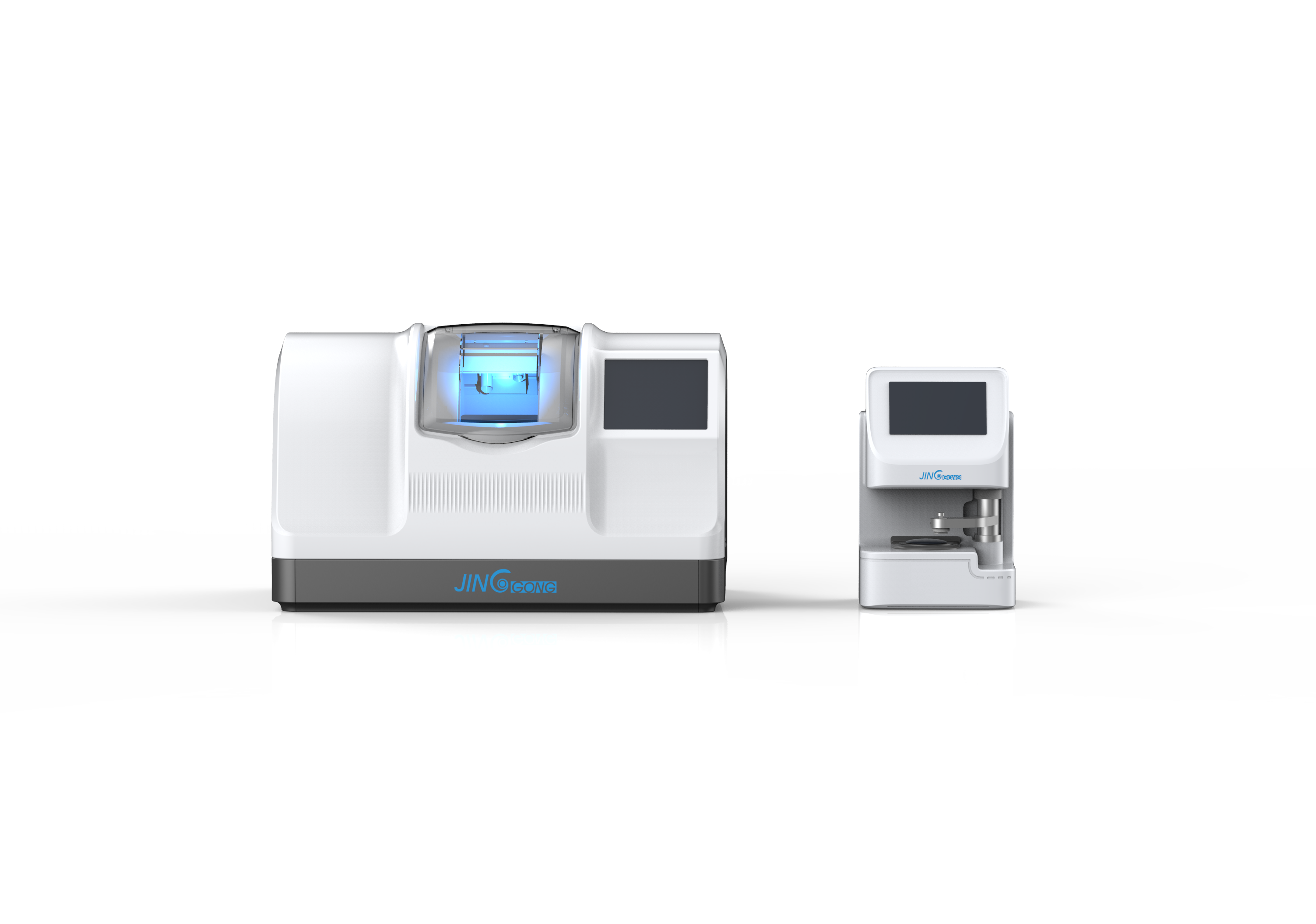

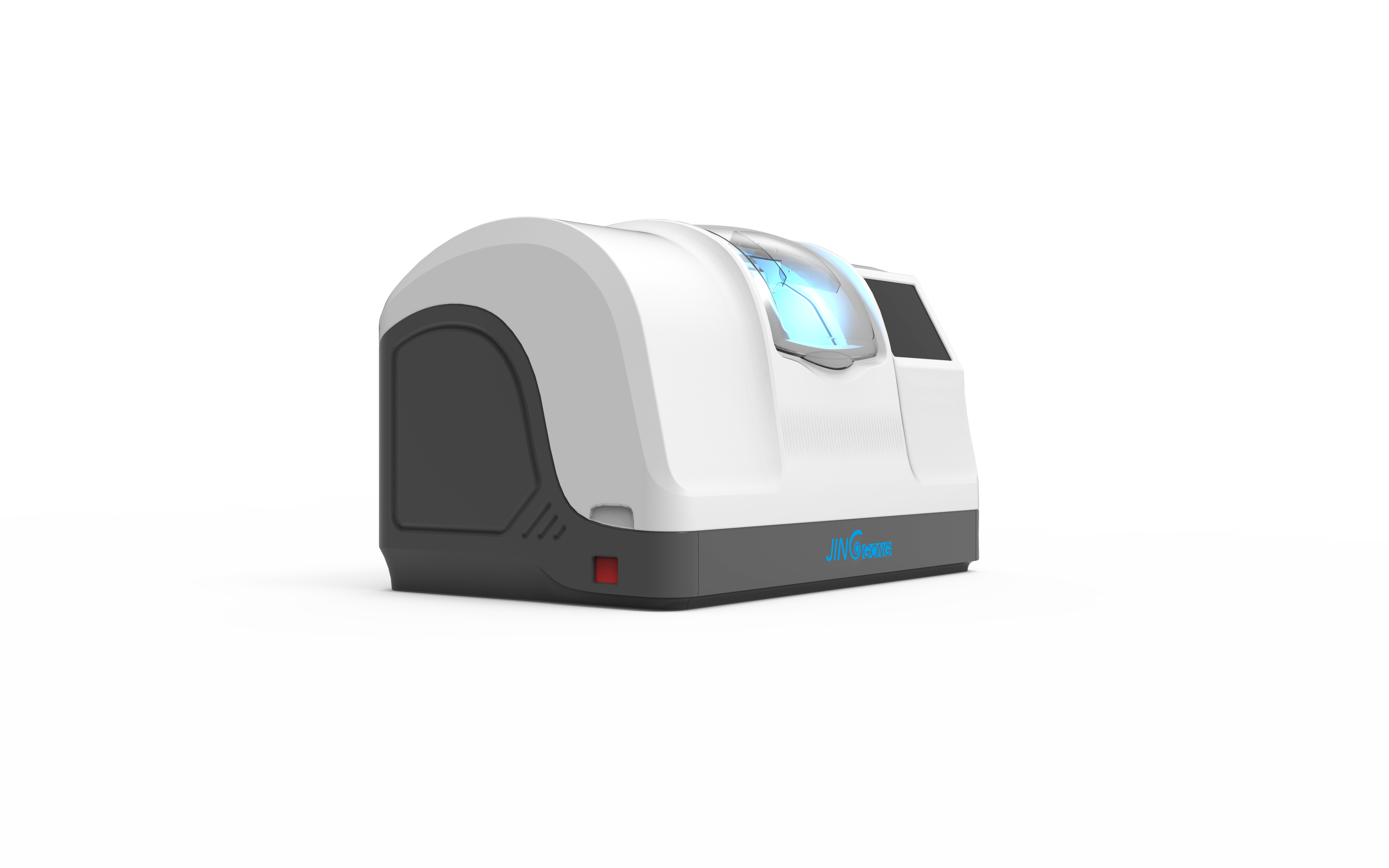

Project Name: Design of edge grinding machine

Cooperation content: design analysis | appearance design | structural design | prototype production | accompanying running assistance

In the field of ophthalmic medical equipment and optical processing, the edge grinding machine is one of the core equipment to realize the precise processing of lenses. From the multiple dimensions of industrial design to show the deep combination of functional orientation and user care, in the rational mechanical structure into the humanized design language, the following from the design analysis, design language, design details, ergonomics four levels of analysis.

1. Design Analysis: Function-First Modular Architecture

The core function of the edge grinding machine is to cut, edge grinding, polishing and other precision processing of the lens, so the underlying logic of the design is "functional modularization" as the core.

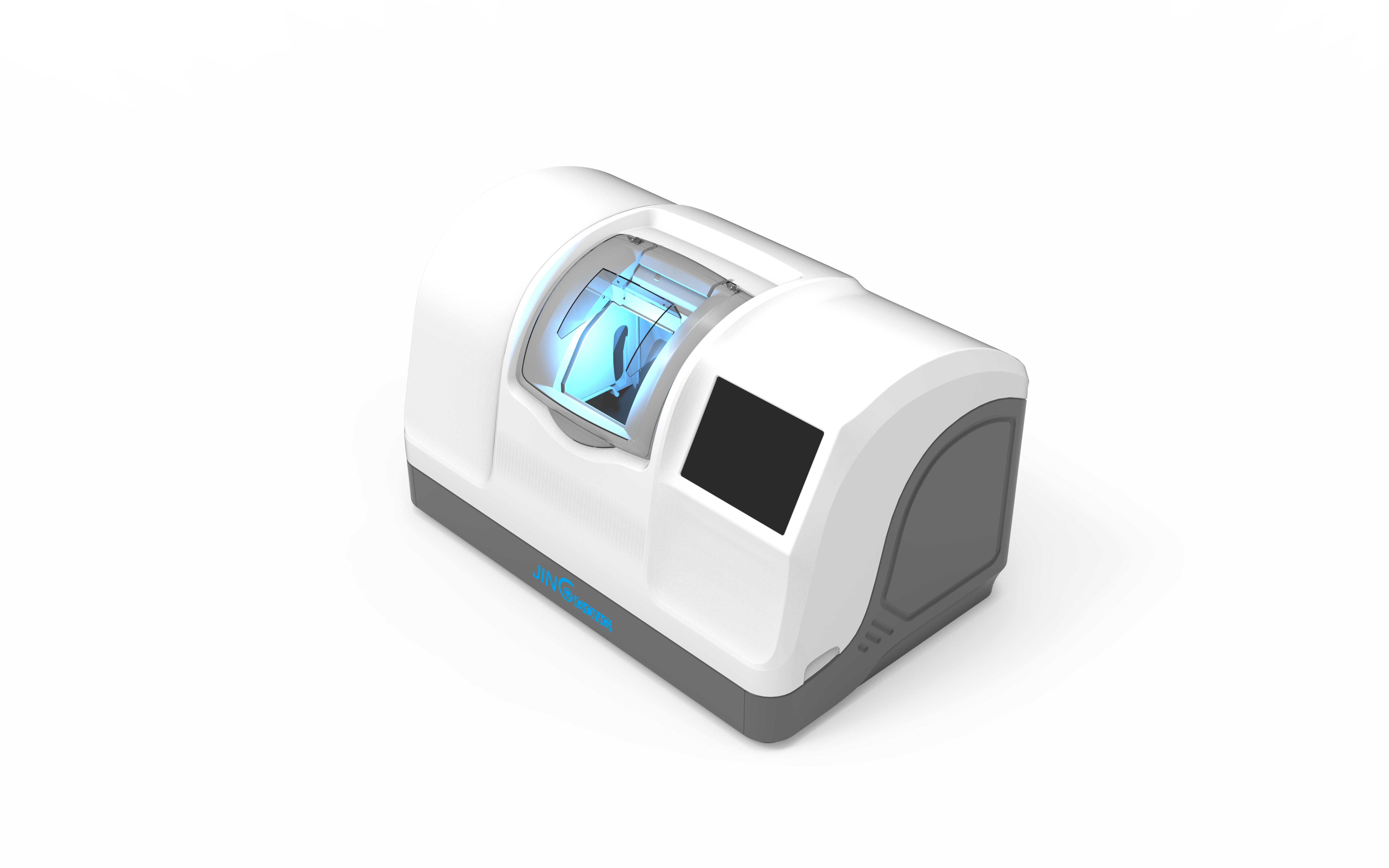

The function division is clear: the whole machine is divided into three main modules-the left side is the power and processing module (integrated motor, grinding wheel and other core components), the middle part is the lens clamping and processing operation area (transparent cabin design), and the right side is the control interaction module (equipped with display screen). This partition makes the working logic of the equipment clear at a glance, and also facilitates later maintenance and troubleshooting.

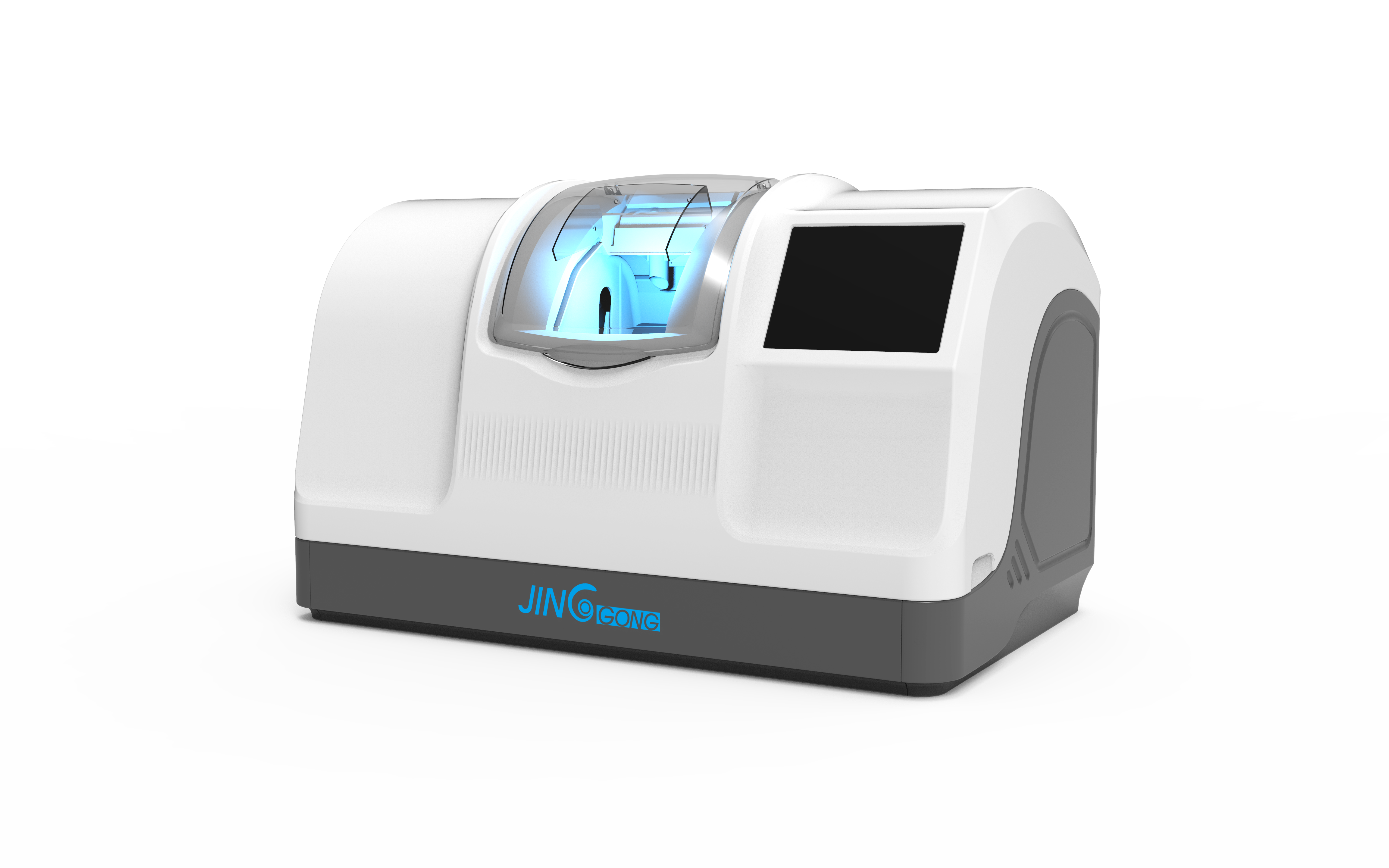

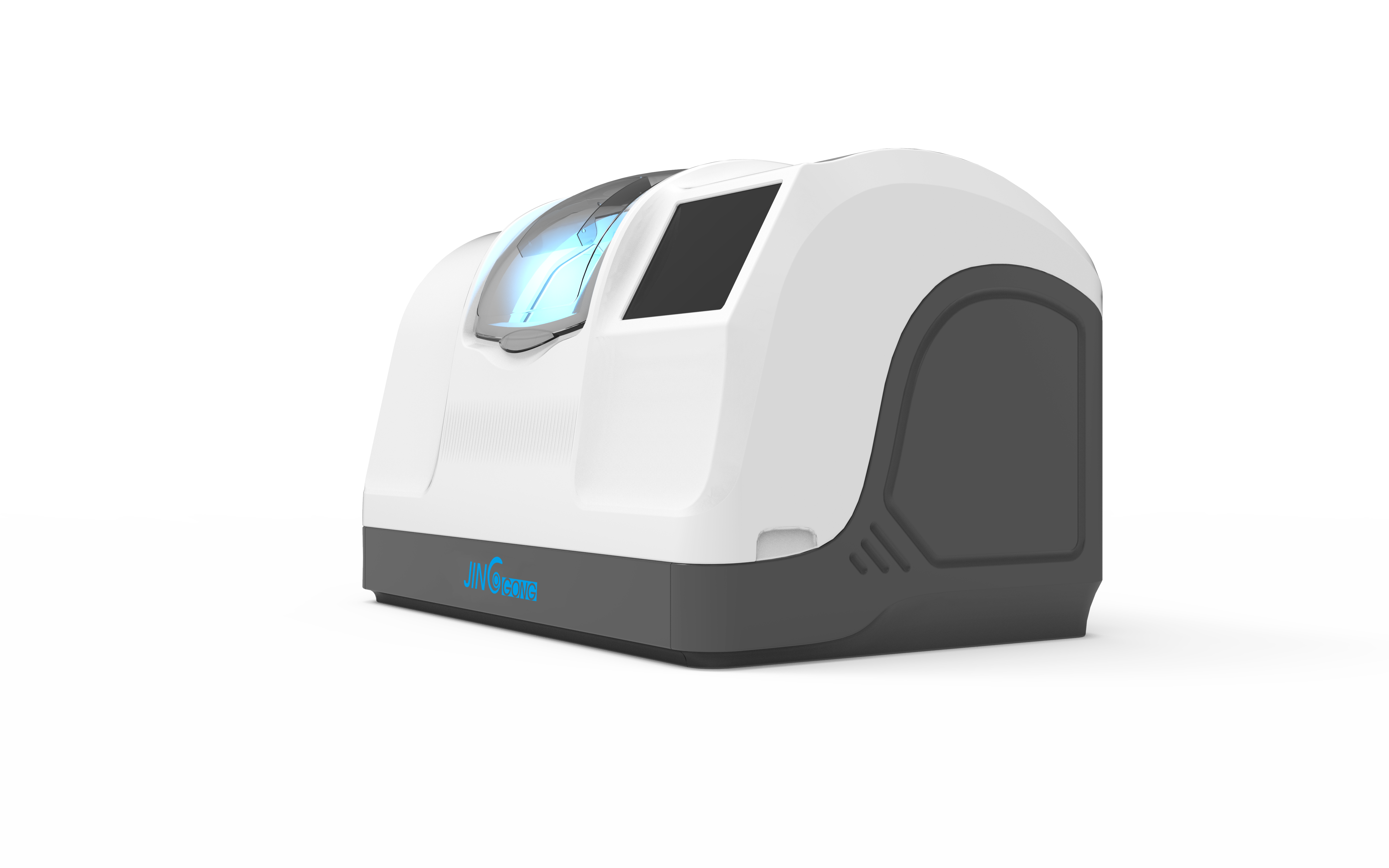

Functional expression of materials and colors: the main body adopts a combination of white high-gloss plastic and dark gray matte plastic, and white conveys "medical-grade cleanliness", which is in line with the scene attributes of ophthalmic equipment. Dark gray strengthens the sense of stability at the bottom and avoids the visual "light feeling" when the equipment is running at high speed ". The acrylic material of the transparent processing cabin has both strength and light transmittance, which not only protects the safety of the operator, but also allows the processing process to be visualized to meet the needs of the process for "precision traceability.

2. Design Language: Visual Narration of Sense of Science and Technology and Sense of Professionalism

The design language of this edging machine is based on "precision technology", which conveys the professional attributes of optical processing equipment through the combination of lines, shapes and light and shadow.

Rational aesthetics of form: the whole machine adopts the form language of "square with circle", and the main outline is constructed with straight lines, reflecting the rigor of industrial equipment. The arc edge of the processing cabin and the rounded corner of the fuselage soften the mechanical sense and avoid visual rigidity. This "combination of hardness and softness" is not only in line with the functionality of industrial equipment (straight lines are conducive to space utilization and structural strengthening), but also conveys psychological care to the operator (rounded corners reduce oppression).

Emotional guidance of color: the use of blue lights in the processing cabin is the finishing touch. Blue is often associated with "technology, precision and calmness", which not only strengthens the "precision processing" attribute of the equipment, but also forms a visual focus-the operator's attention will naturally be attracted to the processing area, which is convenient for real-time monitoring of lens processing. At the same time, blue light also adds a sense of future to the relatively monotonous industrial equipment and enhances the brand's scientific and technological image.

3. Design Details: Humanistic Care Hidden in Precision

Excellent industrial design often see the real chapter in the details, the details of the design of this grinding machine will be "process precision" and "user experience" closely bound.

Details of the transparent processing compartment: the transparent cover of the processing compartment is not a simple "transparent shell". The arc transition of its edge and the tight fit with the fuselage not only ensure dust prevention and safety during high-speed processing, but also improve the visual comfort during operation through smooth form. The mechanical structure layout inside the cabin is clear, and the operator can intuitively see the clamping and processing actions of the lens. This "visualization" design is a detailed expression of "process trust"-allowing the user to see the "professional operation" of the equipment, thereby enhancing confidence in the processing accuracy.

Minimalist design of the interactive area: The display area on the right is designed with a "black frame plane" without extra decoration. This minimalist style is to allow the operator to quickly focus on information reading and instruction input to avoid visual interference. The "JINGGONG" brand logo on the front of the fuselage adopts a blue hollow design, which forms a color echo with the lights of the processing compartment, which not only strengthens the brand identification, but also makes the visual language more unified.

4. ergonomics: making professional equipment "easy to get close"

The operators of the edging machine are mostly optical processing technicians, and long-term operation puts forward requirements for the ergonomic design of the equipment.

Adaptability of operation height: it is inferred from the shape proportion that the operation height of the equipment should fit the natural height of the elbow of the sitting posture of the human body. When the operator places the lens and debugs the parameters, the arm can maintain the natural posture and reduce muscle strain.

Humanization of operation process: the opening design of the processing compartment should consider the action logic of "lens picking and placing", the arc-shaped hatch edge is convenient for hand to reach in, and the operation strength and stroke of the clamping mechanism should also be optimized, so that technicians are not easy to produce fatigue in repeated operations. The inclination design of the display screen needs to ensure that the operator can "read head-up" in the sitting position to avoid misreading of information caused by viewing angle deviation, which is the implementation of the details of "visual ergonomics.

Conclusion: "Function and Emotion Symbiosis" of Industrial Design"

The design of this edging machine is the balance of "tool attribute" and "humanistic attribute" of industrial equipment. It takes function as the skeleton and ensures the processing accuracy through modular design. Taking design language as texture, using form and color to convey the sense of science and technology and professionalism; Taking details as nerves, care for users is integrated into every structure. With ergonomics as the blood vessel, professional equipment becomes "easy to operate and trust".

In the subdivision of optical processing and ophthalmology, this design not only improves the efficiency and process quality of the equipment, but also subtly reshapes the operator's perception of "industrial equipment"-it is no longer cold Machinery, but a "professional partner" with both precision and temperature ". This design logic also provides a reference for the innovation of medical equipment and industrial processing equipment: only by deeply integrating "functional rationality" and "human sensibility" can we create truly competitive products. It also provides a more comfortable operating experience for doctors. Sogo Design: www.soogot.com

本作品版权归 索果设计-专注医疗大健康设计 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

very good

This is too long knowledge