This is the work of graduation design 7 years ago. A personal design of the seat, with the woodworking master polished production.

The original intention is not to leave regrets in the university career, but also to take advantage of the graduation design to give their own four years of time a reply.

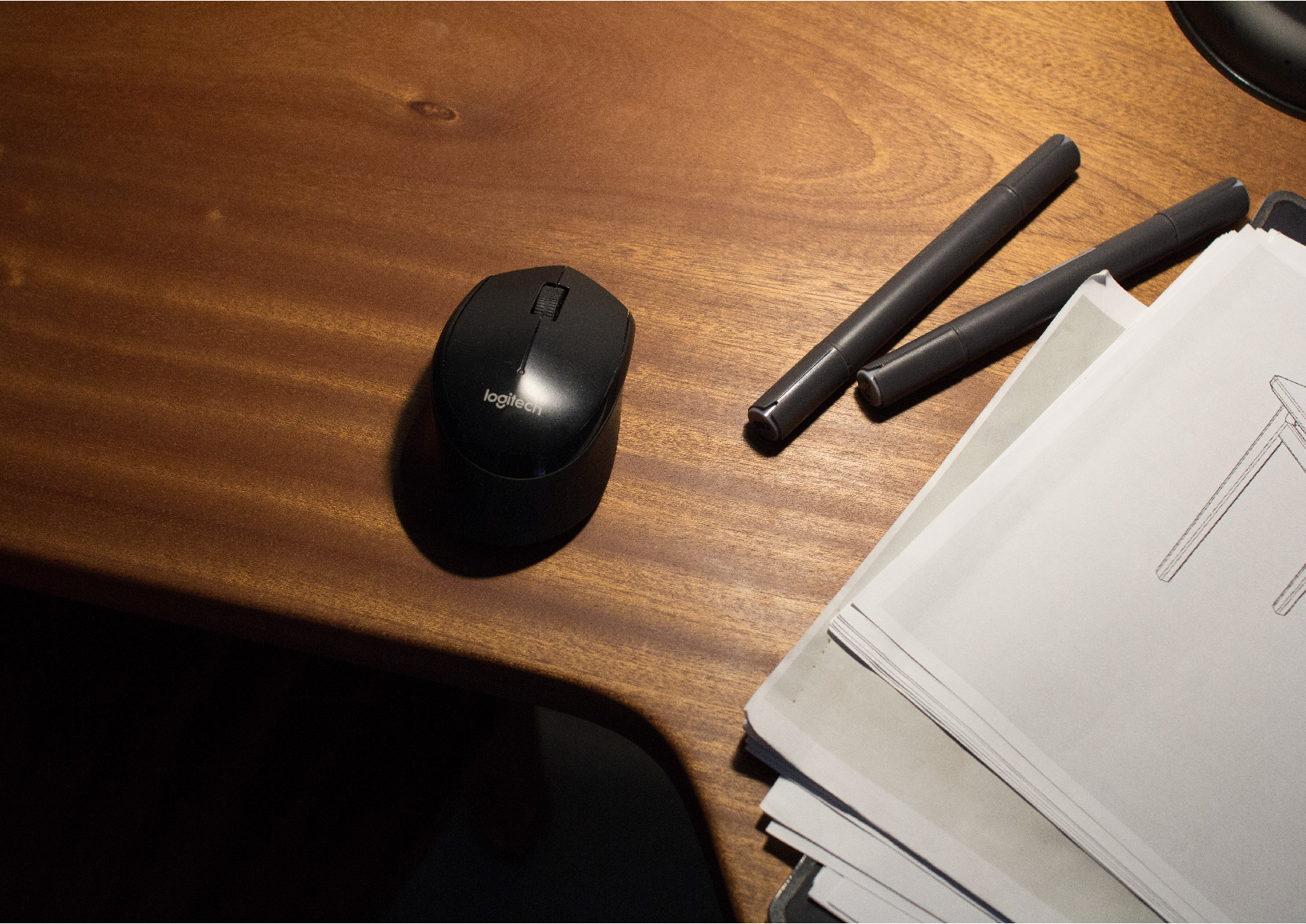

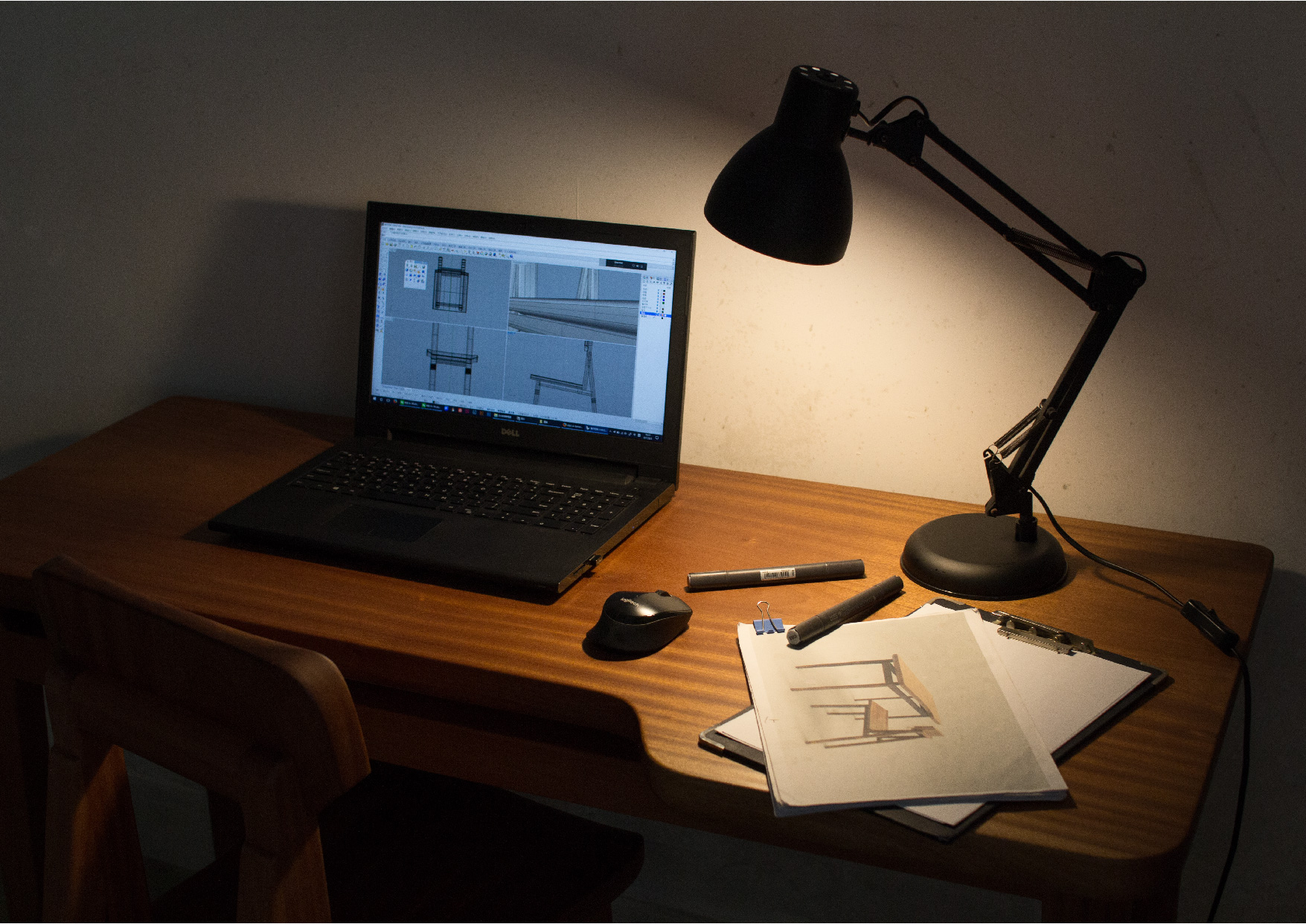

After the sketch diverged and the software built the grass model, he rode a small electric donkey to find a local carpenter who was willing to do it.

Finally, I found a master who was willing to make it together and give me guidance. In retrospect, it is still a valuable experience and memory.

The overall presentation is geometric block splicing, ergonomic curve convergence. Instead of splicing wood boards, whole-cut logs are used to make the layering of the wood grain texture more delicate, while maximizing the use of wood materials. Retain the texture of the wood itself and make the processing curve a modeling element, aiming to return the table and chair to its original function and purpose.

Wood: Sabri

Production cycle: 21 days

Processing technology: tables and chairs are cut from the whole sabri raw board, non-spliced wood.

Structure: full mortise and tenon structure.

Surface treatment: polished wood wax oil.

The wood grain texture is layered and delicate.

The table top and the table legs form a suspended space to reduce the heavy weight of large planks.

This set of tables and chairs has been integrated into the home environment space, the picture shows the environment

本作品版权归 造型食堂ceetang 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

How much did it cost

This one is quite good, huh

nice