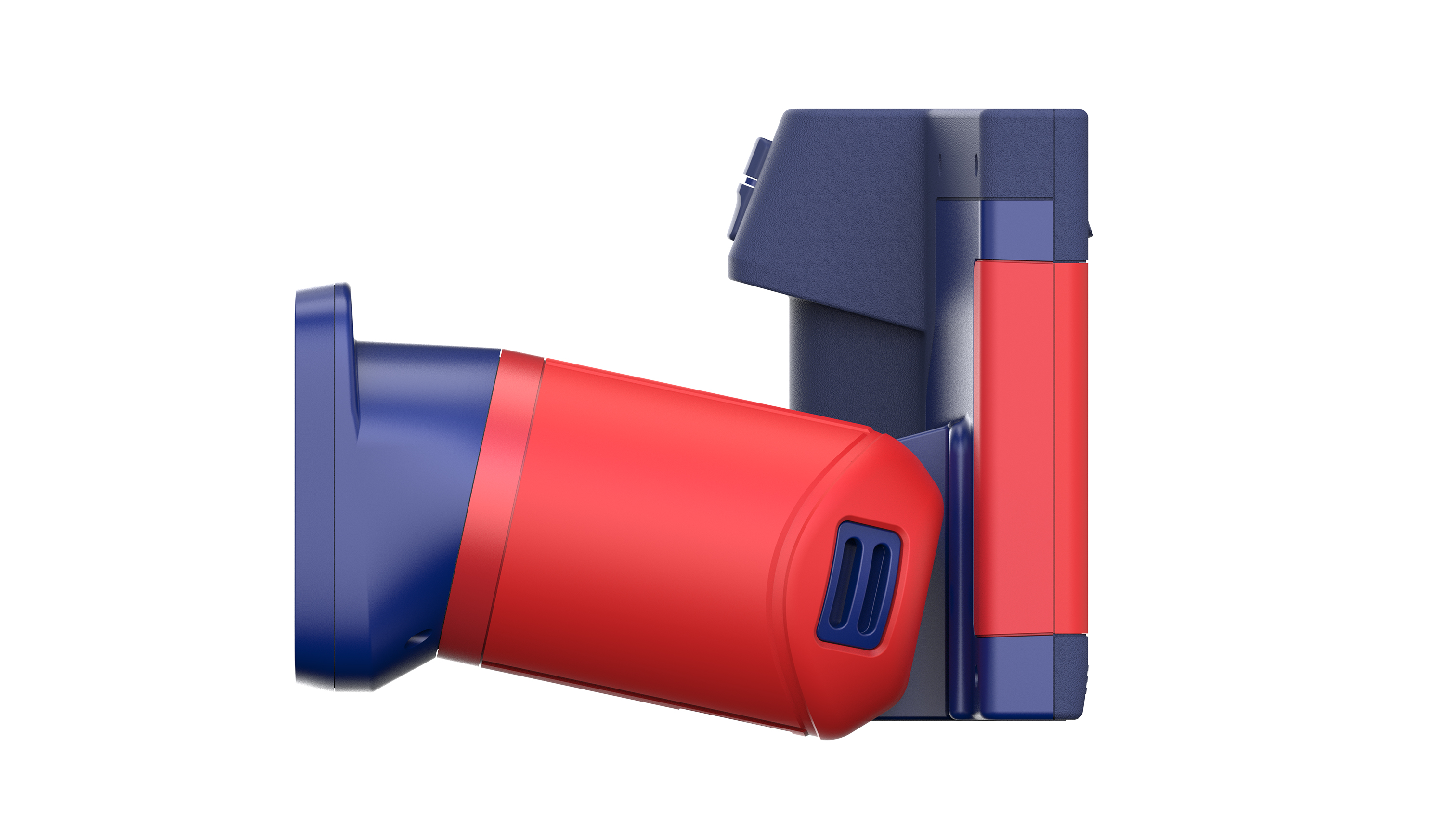

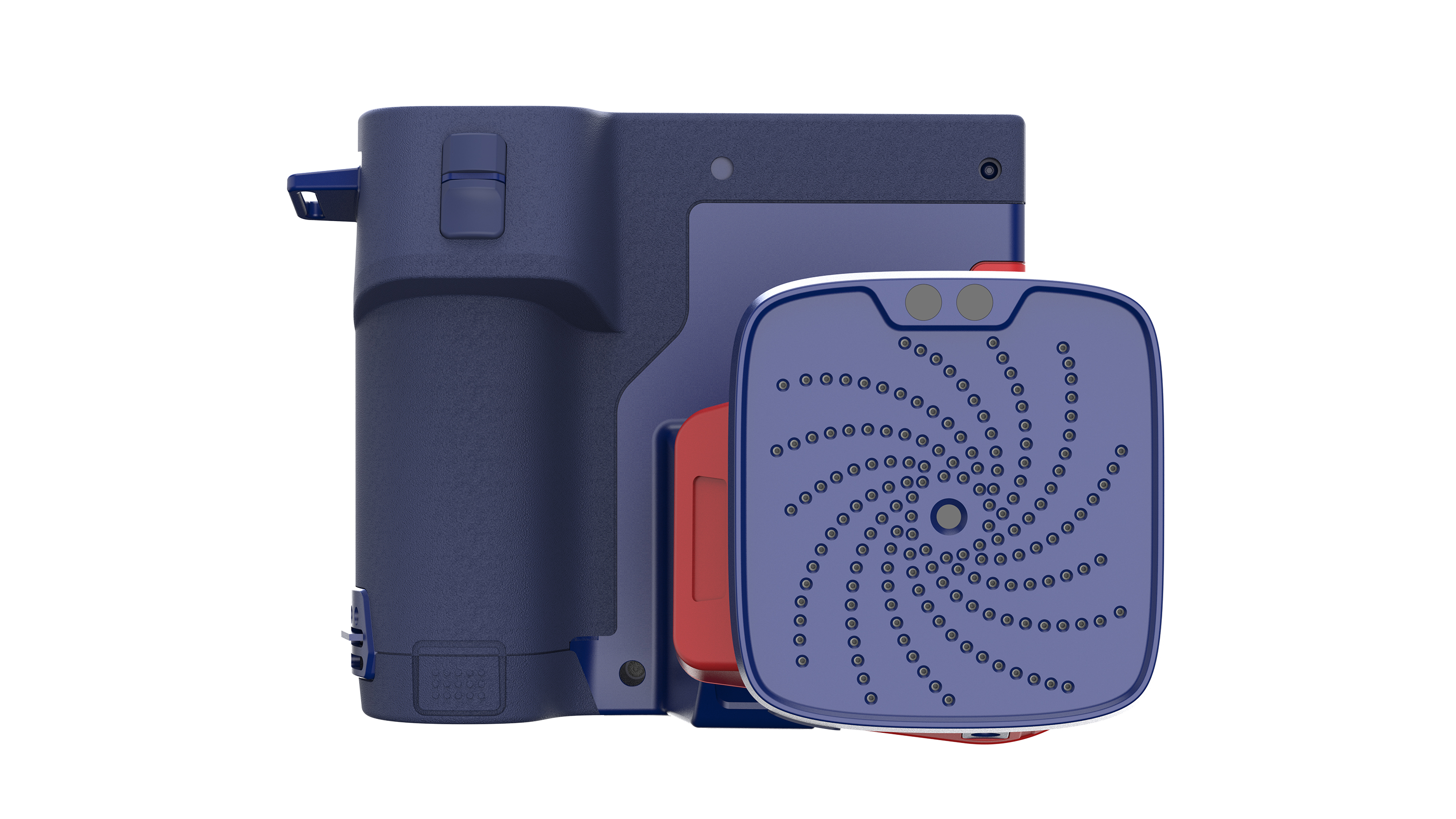

The game breaker came on stage: 180-degree free rotation, redefinition of detection posture for the pain points of the industry, FOTRIC (Flying Foundation) launched a revolutionary product-AC67Flex audio-visual instrument, which realized 180-degree free rotation of audio-visual array and operation screen for the first time, and was matched with FlexAngle "multi-angle locking system to completely free the operator's body shackles.

● Raise your hand without acid: the audio-visual array rotates down to the best angle, and the arm does not need to exceed the shoulder height during high position detection, so as to say goodbye to shoulder and neck strain; · Not tired when shooting overhead: standing posture can complete the observation of the ground target, and the risk of lumbar spine injury is zero;

● Keep away from high voltage: the detection distance is extended to more than 90cm, the risk of arc exposure is sharply reduced, and the protective equipment is more portable to wear.

After the trial, a power plant operation and maintenance personnel sighed with emotion: "In the past, testing a set of equipment had to change various postures, and my back was aching. Now I can handle all positions by standing. It is not tiring to double the efficiency!

Digital Intelligence Inspection: NaviPdM Smart Inspection, Innovating Inspection Process

The liberation of the operator's body posture is the foundation, AC67Flex the deeper innovation lies in the digital reconstruction of the traditional audio-visual detection process, which realizes the leap-forward improvement of inspection efficiency. Its revolutionary integrated NaviPdM inspection system seamlessly integrates advanced audio-visual detection technology with intelligent data management, and constructs a digital closed loop of the whole process from on-site data collection to report generation.

In the traditional process, the operator needs to manually record the equipment information and the name of the audio-visual image on the spot, copy the audio-visual files one by one to the computer after returning, and manually transcribe and check the paper notes and corresponding images on the spot, and finally spend a lot of time on the computer side to diagnose and manually prepare the report according to the industry specifications.

AC67Flex audio-visual instrument has completely subverted the above-mentioned inefficient links. Users only need:

1. Convenient creation of equipment ledger: through code scanning equipment or local entry.

2. Accurately capture acoustic images: complete the core inspection work.

3. This machine generates a report with one key: at this point, the inspection work is completed.

This not only greatly reduces the time cost of manual data recording, sorting, checking and report preparation (usually saving hours), but also significantly improves the immediacy, accuracy and traceability of data, marking the official entry of audio-visual inspection into the era of efficient digital intelligence.

本作品版权归 工业设计师-Damon 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

Fashion

666

color matching is very special