Product structure design plays an important role in industrial design. The emergence of a product must have a reasonable structure, with various product parts, so as to realize the various functions of the product, and finally be manufactured. This is the value of product structure design. The structural design involved in industrial design is mainly the structural design of the external shell of the product. At present, the shell material is mainly metal material formed by sheet metal stamping process and plastic formed by injection molding process. The structural design of common products mainly includes the design of sheet metal structure, the structural design of plastic products, and the overall structure of electronic equipment.

The structural design involved in industrial design is mainly the structural design of the external shell of the product. At present, the shell material is mainly metal material formed by sheet metal stamping process and plastic formed by injection molding process. The structural design of common products mainly includes the design of sheet metal structure, the structural design of plastic products, and the overall structure of electronic equipment.

The design of sheet metal structure mainly includes the structural design of deep drawing parts, blanking parts and bending parts. The structure design of the drawing parts should be uniform and symmetrical in appearance, soft and smooth in contour change, consistent in the width of the top flange, appropriate in the size of the bottom hole, reasonable in overall structural design and good in manufacturability. The structural design of blanking parts refers to the adaptability of blanking parts to the blanking process. A good blanking structure design should ensure high material utilization rate, small number of processes, simple mold structure and high service life, stable product quality, etc. In general, the accuracy requirements and geometric shapes and dimensions have the greatest impact on the structure of blanking parts. Bending is a stamping process that makes the material produce plastic deformation and forms a certain curvature and angle parts. Bending parts with good manufacturability can simplify the bending process and improve the accuracy of bending parts.

The structural design of plastic products includes shape, wall thickness, demoulding inclination, reinforcing ribs, signs, bottom support surface, rounded corners, holes, patterns and other aspects. Good plastic products should be beautiful, easy to use, and easy to form.

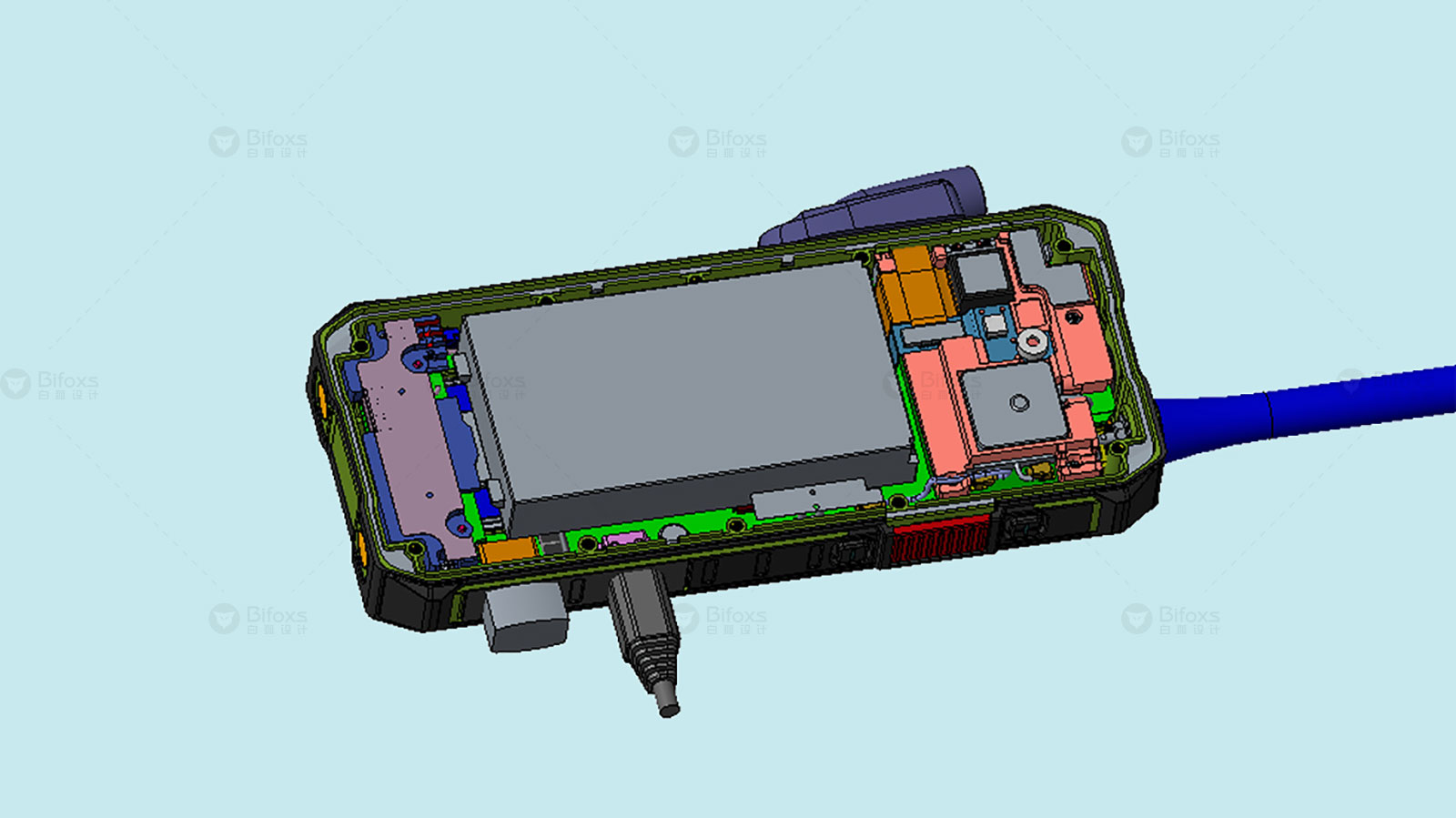

The whole structure of electronic equipment mainly includes the structural form of the chassis, the structural form of the cabinet and the opening form of the ventilation window. Usually, people refer to equipment, devices, instruments, meters, etc. made by the principles of electronics as electronic equipment. The structural design of electronic equipment has its unique structural composition. It needs to install electronic elements, devices, mechanical parts and components inside. Common structures are divided into two types: chassis and cabinet.

To put it simply, the task of product structure design is to determine and draw a specific structure diagram based on the overall design and according to the determined principle plan to reflect the required function. It is to implement the abstract working principle into a certain type of component or component. The specific content is while determining the material, shape, size, tolerance, heat treatment and surface condition of the structural part, it is also necessary to consider its processing technology, strength, rigidity, accuracy and the relationship with other parts. However, the work of structural design is not a simple mechanical drawing. Drawings are only the language to express the design scheme. The concretization of comprehensive technology is the basic content of structural design.

The quality of structural design directly affects the reliability of the product, so there are still many points to be considered in structural design. Reliability is particularly important in product structure design and is an important manifestation of its value.

本作品版权归 白狐设计 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

留言板 (0)

评论为空