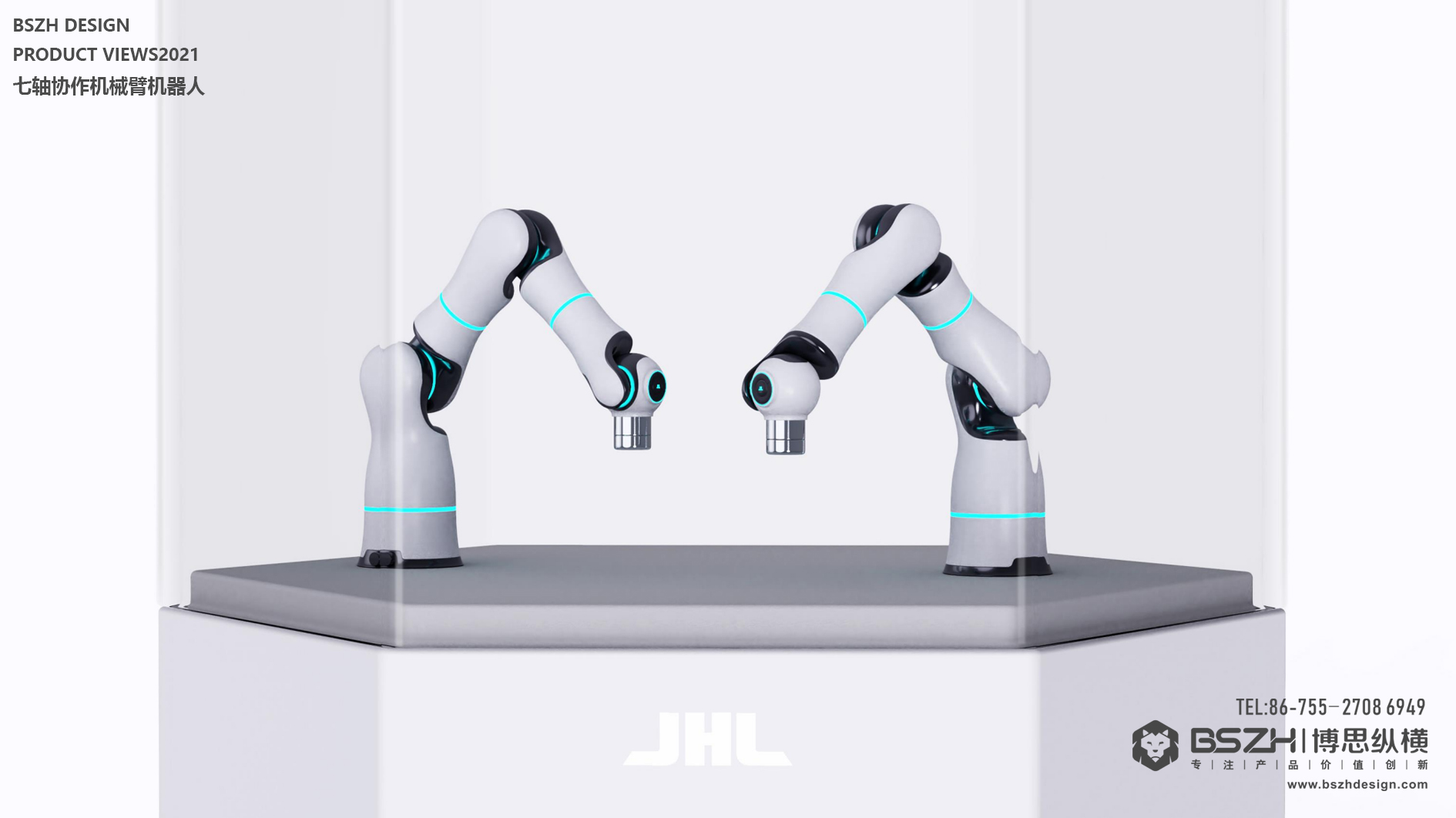

Ji Hua Laboratory | Seven Collaborative Manipulator Design Robot

Service content: industrial design, product design, appearance design, product experience

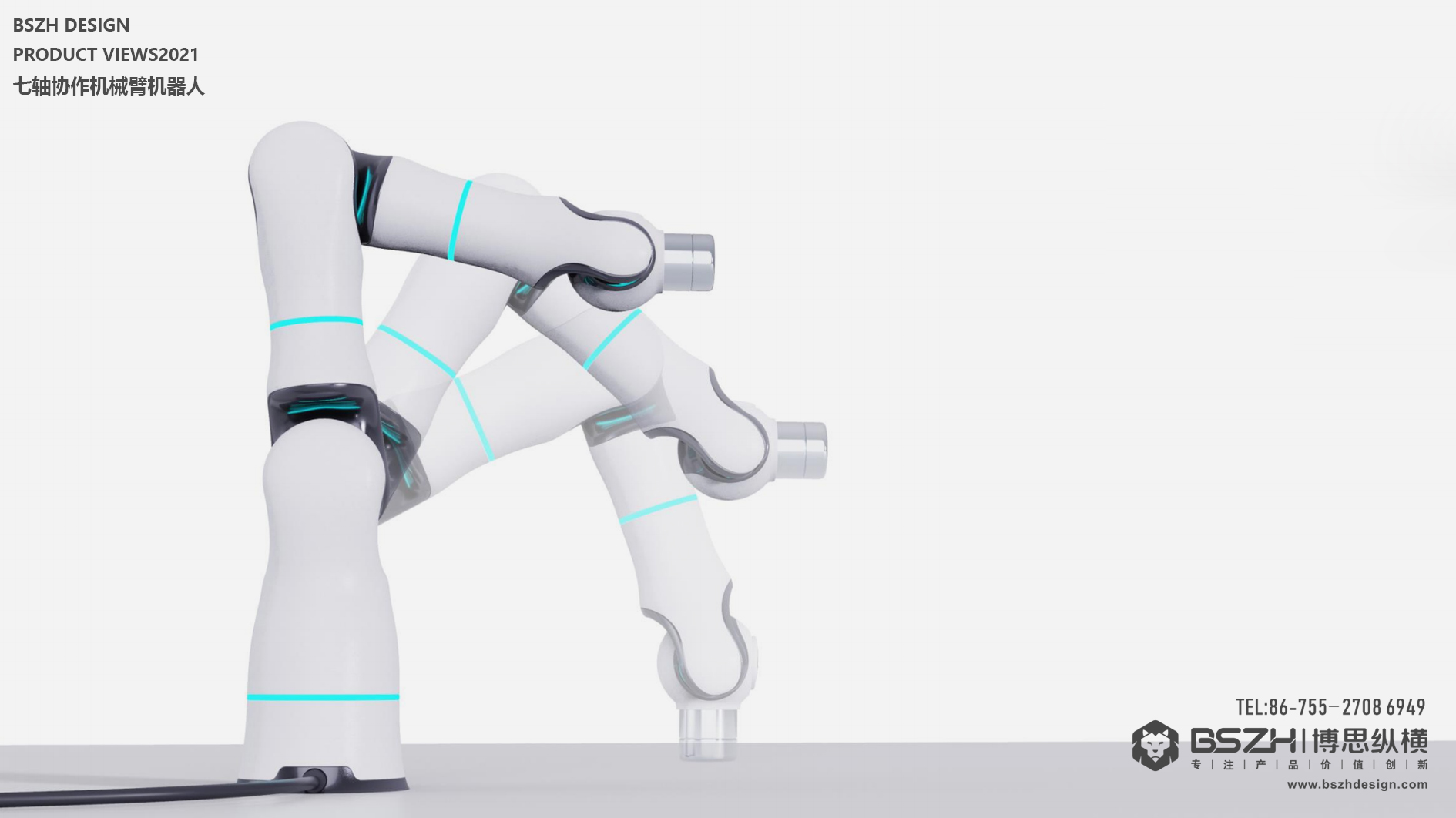

Under the influence of the rapid development of modern science and technology, more and more automatic machinery appears around our life, especially in some large-scale manufacturing or engineering construction, mechanical equipment provides a lot of convenient and efficient work, especially the application of mechanical arm provides a lot of convenience for production and construction. At present, most of the mechanical arms still use pneumatic force to drive the various operations of the mechanical arm, when clamping heavier objects, Wangwang needs to spend a lot of power output to achieve little production effect, which makes the mechanical arm need to consume a lot of energy, and at the same time, it also causes some damage to the toughness of the mechanical arm itself, so as to facilitate long-term production and use. A method for inverse solution of an anthropomorphic seven-degree-of-freedom biased manipulator involves a method for calculating the initial posture of the manipulator in the inverse solution process of the anthropomorphic seven-degree-of-freedom manipulator. The application objects include a space manipulator and a ground manipulator, and can be applied to the task planning of the space manipulator, especially more suitable for obstacle avoidance, and the spatial stereoscopic impression is more vivid. The invention takes the redundant manipulator as the research object, lays a theoretical foundation for the research of related kinematics problems, and conforms to the trend of vigorously developing the robot industry in China, especially the development of space robot and its on-orbit service technology. The research results have certain theoretical and practical significance for the practical application of space robot on-orbit service in the future.

本作品版权归 博思纵横咨询设计 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

I like it.

Not bad, huh

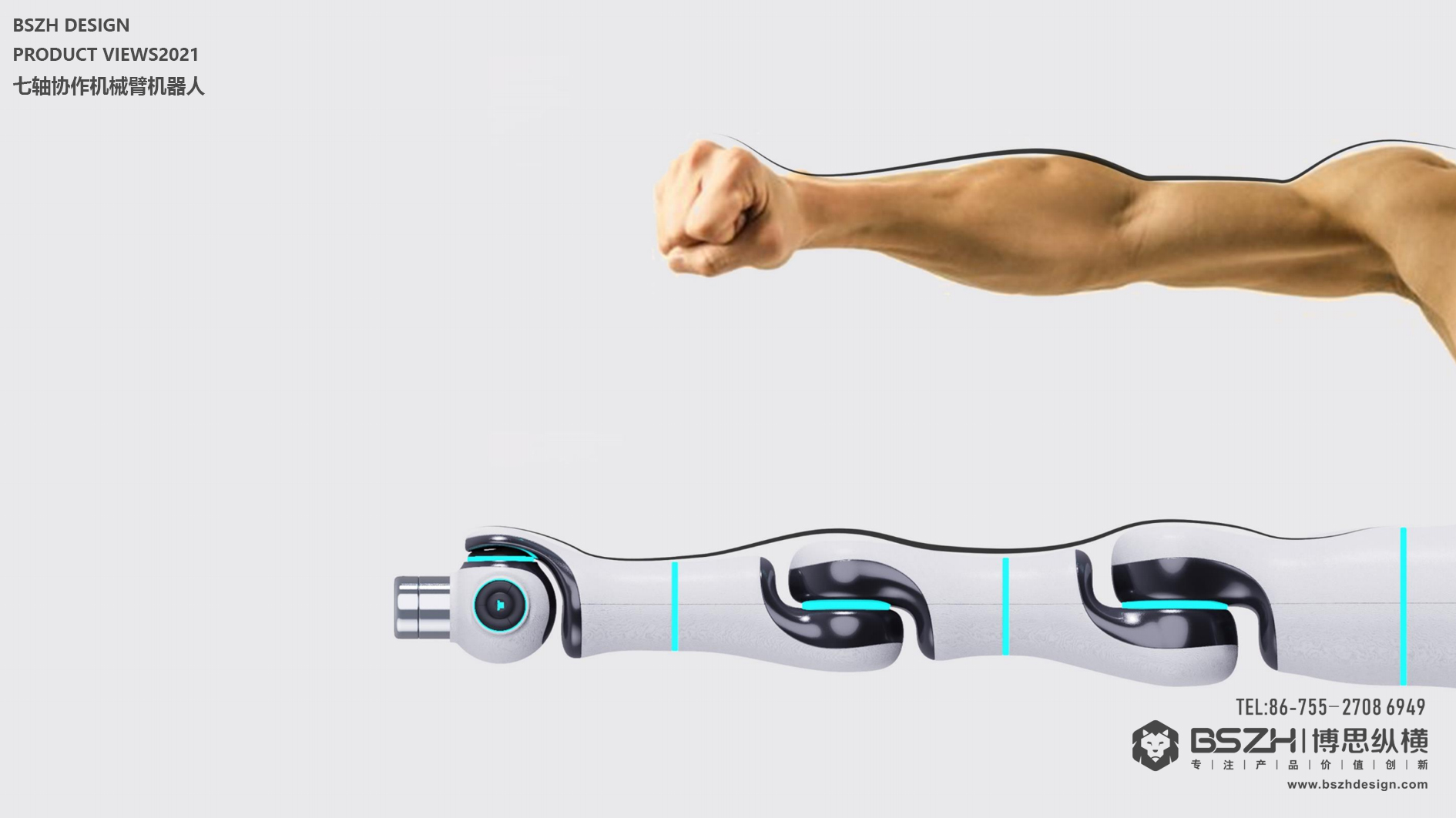

Ergonomics

Come on

Visual inspection is very flexible.