The reason was that when the express was unpacked, it was found that the express knife was rusty, so it decided to buy ceramic blades and design an express knife by itself with the help of a 3D printer.

Ceramic blade to hand, is really sharp!

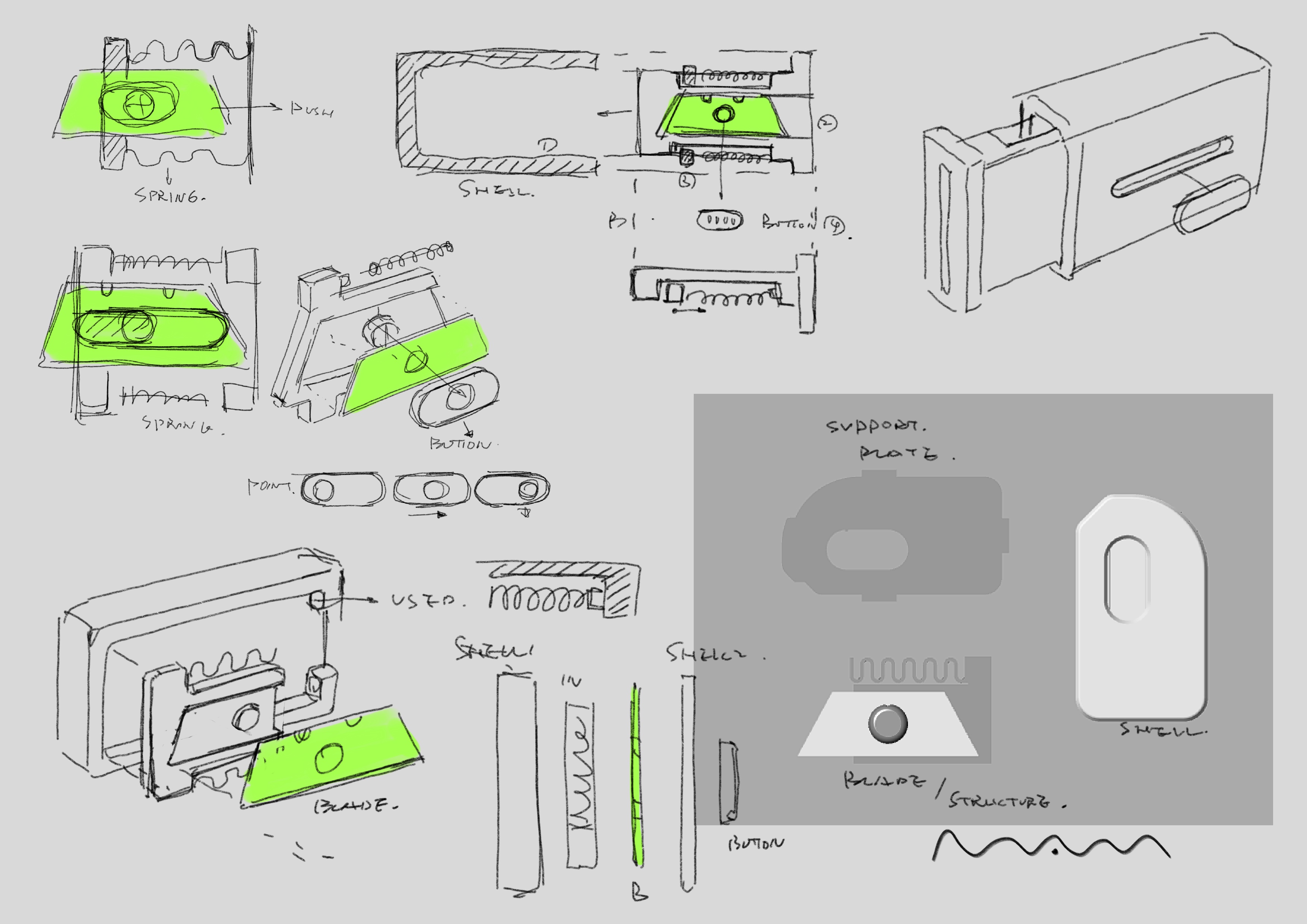

The sketch roughly drew the basic idea and structure, ready to use the properties of the material itself to make the spring.

At first, it was done in the form of a compression spring. It was tested twice and failed.

Then use the form of a tension spring, after adjusting twice, it is found that the feasibility is higher.

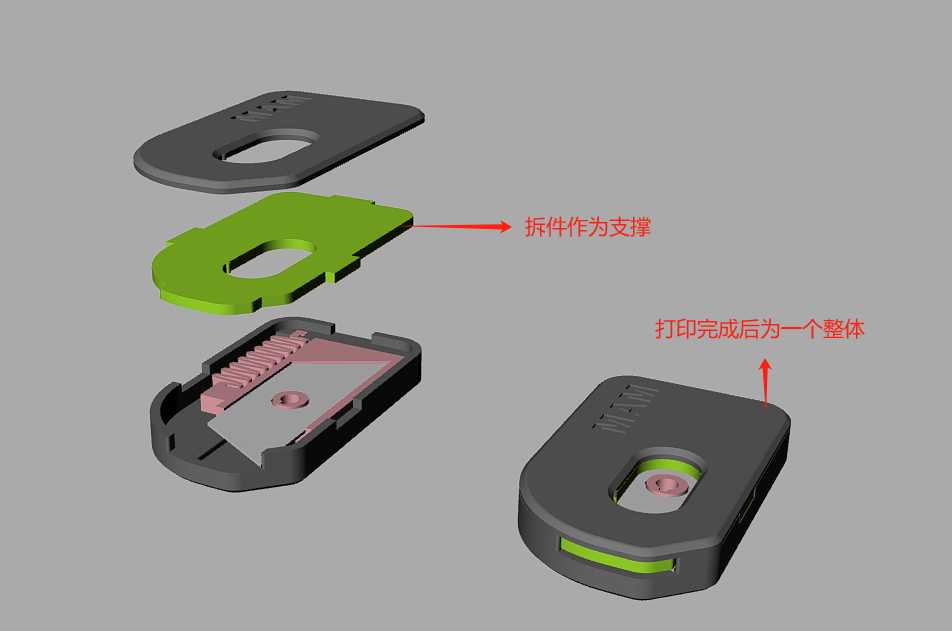

A wrong decision was made here to print the knife into a whole in 3D (if the function is not OK after proofing, there is no way to use it twice, and the subsequent proof is indeed the case).

However, there is a good way for 3D printing to hang in the air, which is to split a whole into several parts according to the specific situation, and print the detached parts as supports in advance. After that, when printing the main body, a pause is added to the corresponding layer, and the supporting member printed in advance is placed in the corresponding position to support the subsequent suspended part.

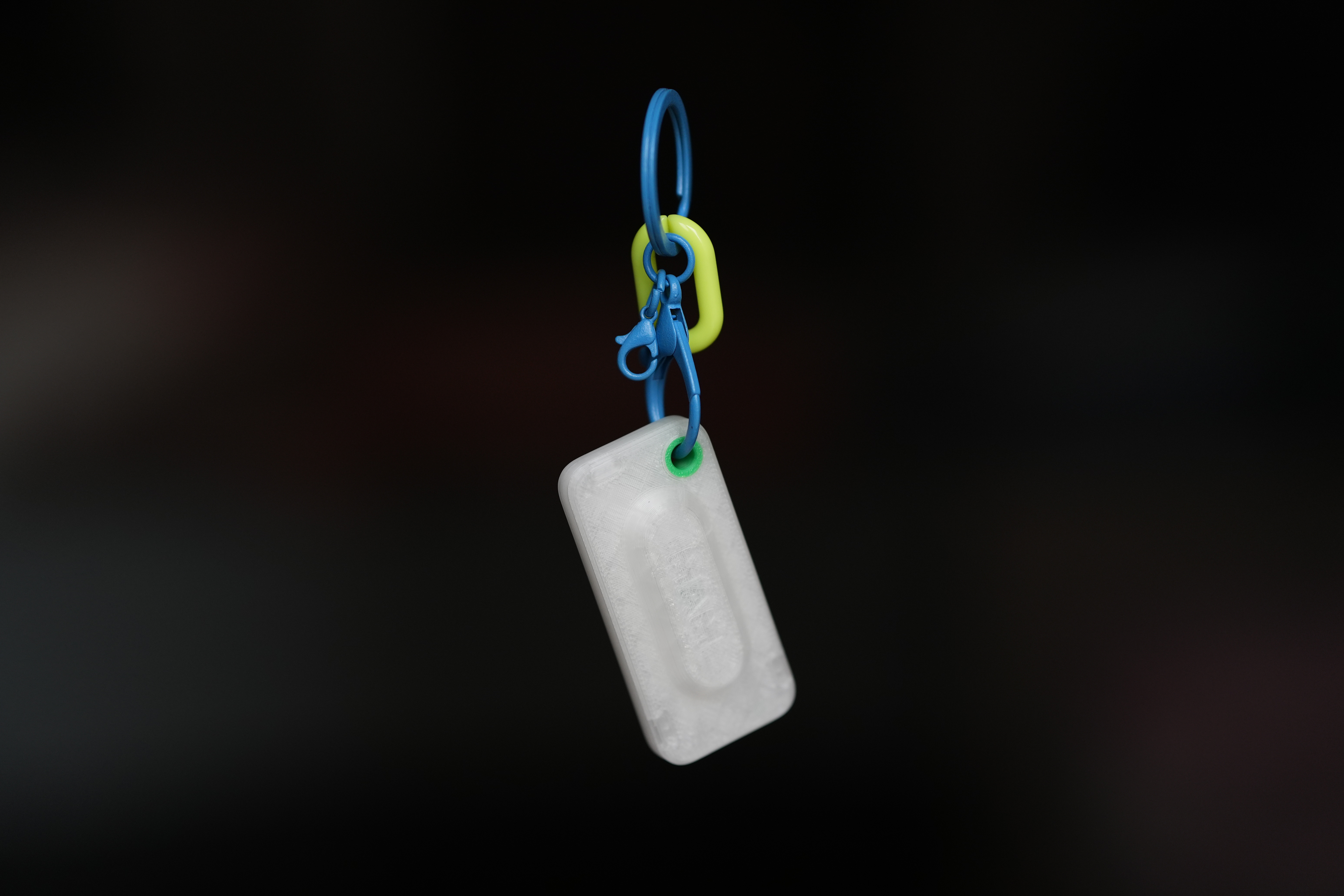

The first DEMO can be used, but it is not easy to use.

After the blade is pushed out, the blade cannot be fully retracted due to the range of elastic deformation of the material.

Demolition!

Decisive choice to use the spring.

Want to do a partial hard core look, draw.

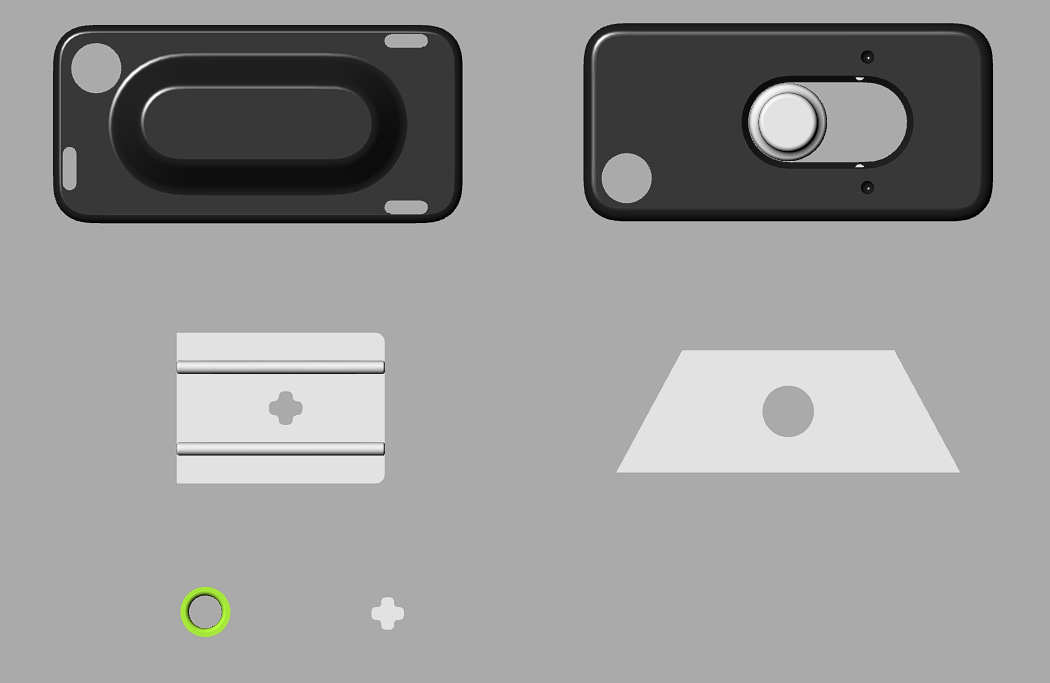

The whole print out to see the effect, the thickness and slope of the recessed part lead to direct naked leakage of the layer pattern, not so good, gave up.

It's still a bit simple, and I went to modeling before I finished drawing the picture.

Dry model

Here again, the blade is supported as a support in a suspended position. (Add pause before printing suspended)

Iterated three or four times (mainly for tolerance problems), the final part came out.

Assemble a wave.

There is a corresponding card point at the end of the trip, which can be fixed here.

Family photo.

本作品版权归 马啊马 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

It is suggested to improve the appearance of good looks.

pla for material? The spring should not be so straddling

this is good

nice