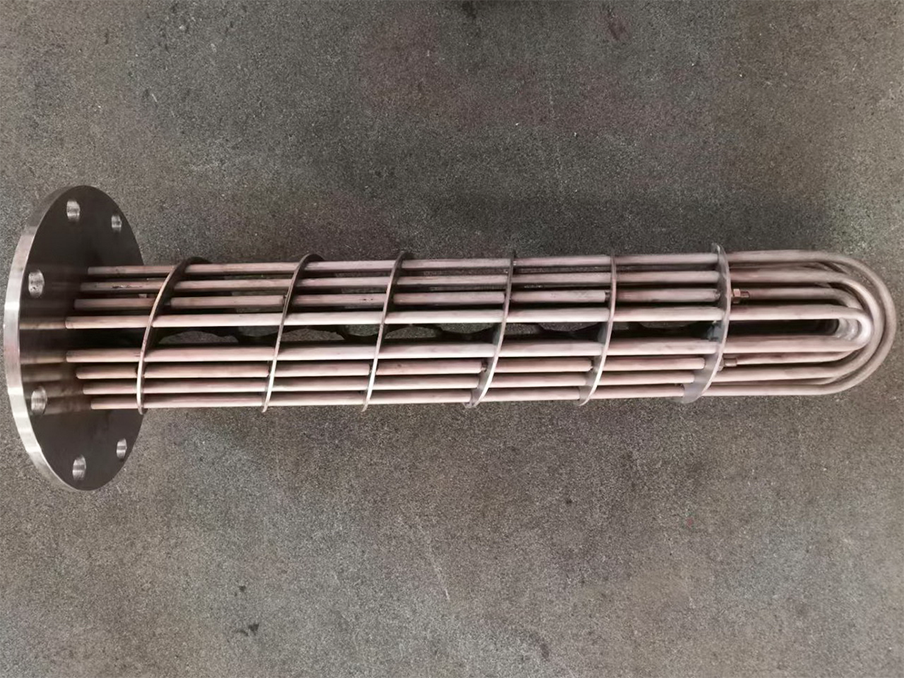

In the field of industrial heat exchange equipment, cost and efficiency are the key to enterprise decision-making. The continuous spiral baffle heat exchanger invented by Wuhan over-control has become the preferred selection of many enterprises by virtue of its excellent quality and people-friendly positioning.

Wuhan's over-control strength is escorted, and the price is similar to that of the bow-shaped baffle heat exchanger. Wuhan's over-control deep-tilling heat exchange equipment has been developed for many years. Through the renewal and upgrading of processing technology, the manufacturing cost of the continuous spiral baffle heat exchanger has been effectively reduced. This makes the continuous spiral baffle heat exchanger to ensure high quality at the same time, the price can be basically the same as the traditional bow baffle heat exchanger. Enterprises choose Wuhan over-controlled products, without having to bear additional equipment upgrade costs, you can enjoy more advanced heat exchange technology.

The production efficiency is not inferior, and Wuhan over-control technology casts quality: Wuhan over-control has invested a lot of energy in the research and development of continuous spiral baffle heat exchangers. The efficiency performance of this equipment is the same as that of bow baffle heat exchangers, and even has advantages in some scenes.

Greatly improve the heat transfer efficiency: Compared with the traditional bow baffle heat exchanger, the flow dead zone of the spiral baffle heat exchanger is greatly reduced, and the heat exchange area can be fully utilized. At the same time, the spiral flow of the fluid produces a velocity gradient at the radial interface, forming a turbulent flow, and the shell-side heat transfer coefficient can be increased by 5 to 20%. Under the same heat load, the size of the heat exchanger can be significantly reduced, and the investment cost of the equipment can be reduced.

Significantly reduce the shell side resistance: in the traditional bow baffle heat exchanger, the fluid flows in the shell in a "Z" shape, and the direction changes violently, resulting in a large pressure drop. In the spiral baffle heat exchanger, the fluid is in the shell side of the overall spiral propulsion, the direction change is gentle, under the same working conditions, compared with the bow baffle, the shell side resistance can be reduced by 20 to 50%, greatly reducing the operating energy consumption of the system. In addition, Wuhan over-control pays attention to the durability of the product. The continuous spiral baffle heat exchanger reduces the fouling phenomenon, prolongs the service life of the equipment, and reduces the maintenance frequency and cost.

Reduce the fouling rate: the bottom corner of the bow baffle is easy to form a flow dead zone, and dirt is easy to accumulate. In the spiral baffle heat exchanger, the spiral flow of fluid can wash particles and sediments along the surface of the spiral baffle, thus reducing the fouling dead angle, reducing the fouling rate, prolonging the cleaning cycle and service life of the heat exchanger, and reducing the maintenance cost.

Improving vibration and noise: The traditional bow baffle heat exchanger often produces fluid-induced vibration in the heat exchange tube bundle at large Reynolds number, which easily leads to leakage failure of the heat exchange tube. The restriction of the heat exchanger with spiral baffle plate on the heat exchange tube is stronger than that of the bow baffle plate, so that the tube bundle is no longer washed by the fluid alternately, the vibration of the tube bundle is reduced, the stability of the tube bundle is enhanced, the possibility of failure of the heat exchanger due to mechanical damage is reduced, the reliability and stability of the equipment operation are improved, and the operating life of the equipment is prolonged.

The continuous spiral baffle heat exchanger invented by Wuhan over-control brings excellent production efficiency and comprehensive benefits at a price similar to that of the bow baffle heat exchanger, and is a reliable choice for enterprises to enhance their competitiveness.

本作品版权归 武汉过控科技 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

留言板 (0)

评论为空