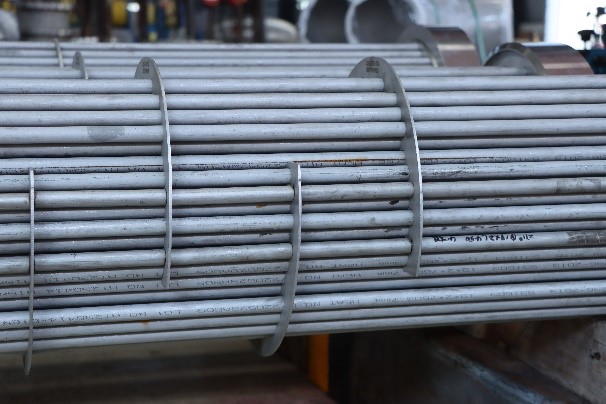

Did you know that with the same budget, you can have a continuous spiral baffle heat exchanger with 5% ~ 20% higher comprehensive performance and half of energy consumption than a traditional bow baffle heat exchanger!

Core data comparison:

The heat transfer efficiency is increased by 5 ~ 20%: due to the continuous spiral plunger flow formed by the spiral channel, the flow dead zone is eliminated, and the heat exchange area can be fully utilized;

The operating pressure drop is reduced by 20-50%: the shell side fluid flows along the spiral surface to reduce the pressure loss;

Reduced fouling rate: the fouling is washed away along the surface of the spiral baffle, reducing the flow dead zone and reducing the fouling rate;

Improve vibration and noise: the fluid is continuous spiral flow, and the transverse flow is weak.

Why is the price similar to that of traditional bow baffle heat exchangers?

Technology upgrade: continuous spiral baffle processing core process innovation, rapid production;

Efficiency improvement: large-scale production, efficiency increased by 5 times compared to the original;

The choice of continuous spiral baffle heat exchanger is to choose an efficient, energy-saving and reliable heat exchange solution. Contact us now to start your efficient heat transfer journey!

本作品版权归 武汉过控科技 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

留言板 (0)

评论为空