Active Needle Technology is a company specializing in ultrasound technology for needle-based medical surgery, initially focusing on medical applications such as ultrasound-guided injections and biopsies. Their technique uses ultrasonic vibration to significantly reduce pain and skin trauma.

They realize that the technology has wider application potential, especially in the tattoo market, where pain management can greatly enhance the user experience. They chose to work with the UK IDC team to develop a new product-a tattoo device.

Project Background and R & D Challenges

The company has tried to make a tattoo device by adapting its technology to reduce the pain of tattooing.

However, they encountered two major challenges:

Excessive weight and vibration: The ultrasonic transducer required to produce high-frequency vibration is heavy, and the reciprocating mass of the equipment causes the equipment to vibrate too much. This means that the device vibrates so much that it is almost impossible to hold, and it is impossible to safely tattoo.

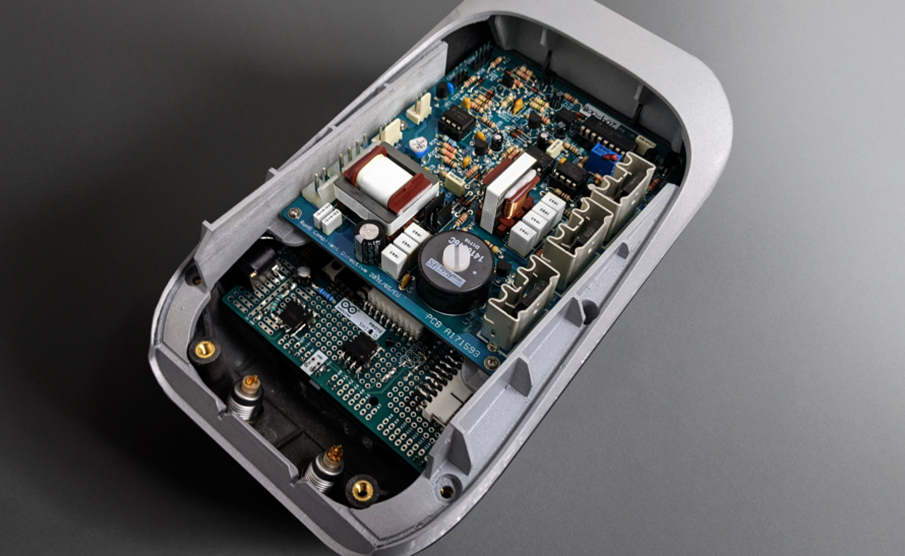

Wiring and durability issues: The transducer needs to be powered by a wired connection. As the device moves back and forth quickly at a 9000 r/min speed, the wire quickly breaks. Continued application of stress to the wire does not allow the device to operate reliably.

Vibration Control and Durability Solutions

The first approach is to develop a balanced system.

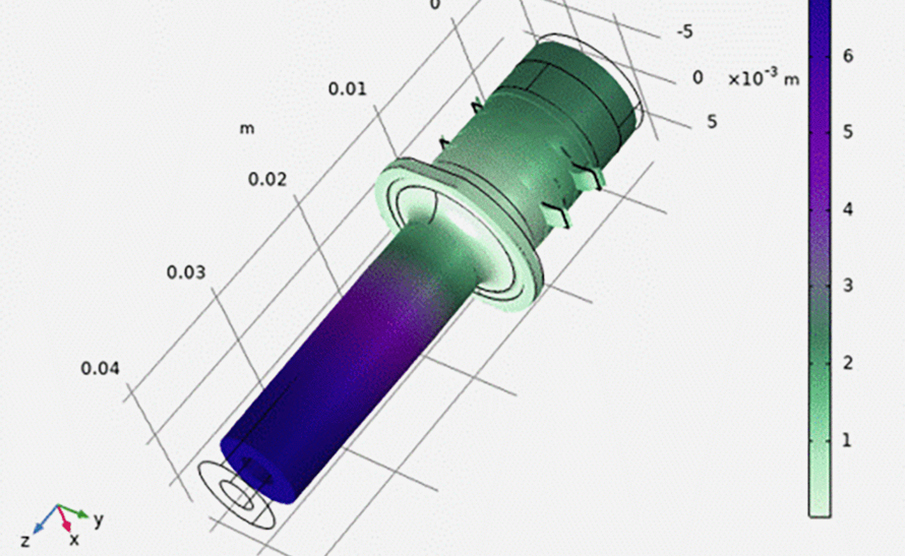

The IDC team's goal is to counteract forces and reduce vibration by moving the balance weight in the opposite direction of the sensor. Preliminary tests show that the vibration amplitude is reduced.

But this is not enough, because the mass of the universal tattoo device transducer is 10 times the moving mass of a typical tattoo device, and due to the misalignment of the moving mass, it will also generate vibration in an unexpected direction.

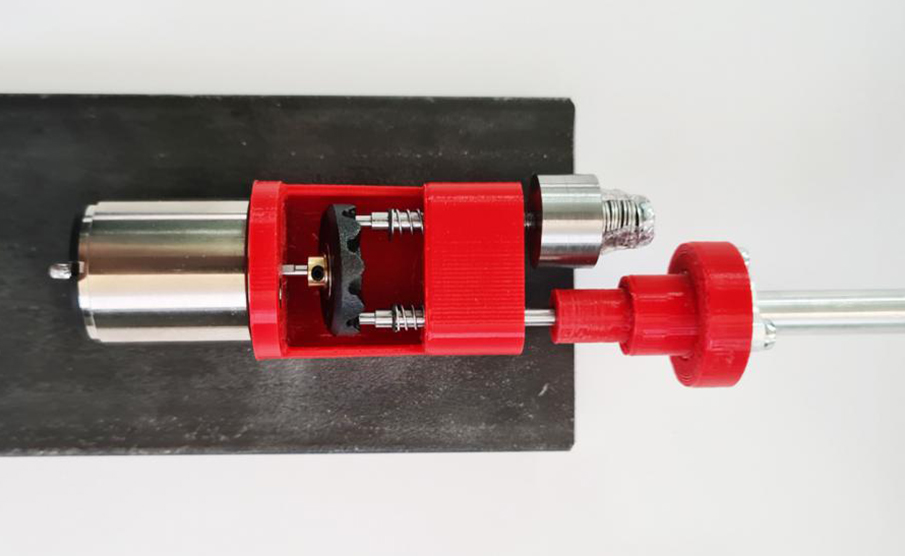

Subsequently, the team improved the design so that the balance weight was directly aligned with the transducer. This requires a dual-output-shaft motor to enable full relative movement of the two balance weights.

We made prototypes and conducted extensive testing, which showed improved damping, but also found that increased forces on bearings and other components would lead to rapid wear and mechanical failure.

A motor that can change power according to the mechanical load is added to the system, so that the speed of the equipment is more consistent, reaching the millisecond level. Customized components, including a specially designed motor shaft with welded hubs, help to further improve the equipment and effectively control vibration.

User-Centered Design

In addition to the mechanical challenges, the IDC team focused on designing a user-friendly product to appeal to tattoo artists.

We interviewed experienced artists to understand their ergonomic needs and develop hand-held sections and consoles suitable for the artist's work environment.

Significant effect in reducing pain

To TranQuill®Extensive tests conducted by the device have shown that it is effective in reducing pain during the tattooing process.

In the trial, the participants' average pain score decreased from 8 out of 10 (no ultrasound) to 3 out of 10 (ultrasound activated), demonstrating a significant improvement in the tattoo experience.

The project not only solves complex engineering problems, but also demonstrates the potential of ultrasound technology in new markets, and is currently exploring its further application to medical tattooing of scars and burns.

IDC's design and development process highlights the importance of iterative design, user feedback and innovative engineering solutions to create breakthrough products.

Customer Evaluation

"We are delighted to be taking forward this project with the valuable assistance of IDC. The project, which was partially funded by the UK Innovation Agency (InnovateUK), produced an advanced prototype that allowed the company to license the technology to a leading tattoo company."

-- Ian Quirk, CEO, Active Needle

Product Design Delivery from IDC UK

IDC UK in TranQuill®Design work involved in the project:

• Solving mechanical problems

• Vibration analysis

• Test rig design and construction

• Vibration testing and iteration

• Component specification determination

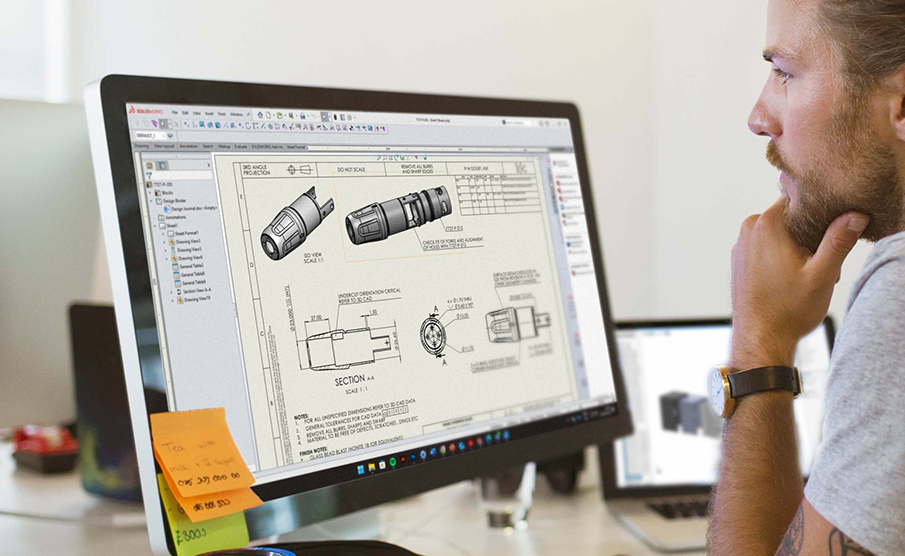

• Detailed design for production

• Material specification determination

• Prototype manufacturing

• Engineering Drawings

• Appearance and CMF design

• Digital and physical user experience design

• Electronic hardware and software engineering

• Production support

For further details, please see: https://www.idcdesigncn.com/consumer/tattoo-device/

To learn more about IDC's innovations in the UK, please see: https://www.idcdesigncn.com/medical/cases/

Welcome to contact the UK IDC team: https://www.idcdesigncn.com/contact/

本作品版权归 英国IDC产品设计 所有,禁止匿名转载及个人使用,任何商业用途均需联系原作者。

新用户?创建账号

登录 重置密码

请输入电子邮件以重置密码。

Invincible

Follow the bosses to learn

this is good